-

The Adjustable Gooseneck Low Flatbed Semi-Trailer has emerged as a game-changing solution for industries that rely on transporting oversized or heavy equipment. From construction machinery and industr...

READ MORE -

In the world of modern logistics and heavy cargo transportation, efficiency, stability, and adaptability are key. The KTG-4 hydraulic axles line trailer with 4 axle (SPT) stands out as a powerful solu...

READ MORE -

Precision Engineering and Stability: The Core of the Low Flatbed Precision Instrument Transport Semi-Trailer At the heart of the Low Flatbed Precision Instrument Transport Semi-Trailer lies a meticulo...

READ MORE -

What Is a Wind Turbine Tower Bridge and Why Is It Essential? The Wind Turbine Tower Bridge is a specialized structural device used during the assembly of wind turbine towers. Its main function is to c...

READ MORE

What are the design and functional differences between international SPMTs and standard flatbed trailers?

In the global field of large-scale engineering and heavy-duty transportation, the technological level of transport equipment directly impacts project safety and efficiency. While standard flatbed trailers are widely used in traditional cargo transport, the international SPMT (Self-Propelled Modular Transporter) represents a high-end solution for oversized cargo transport. Since its establishment in 2020, Hangzhou Kotter Intelligent Manufacturing Co., Ltd., a company specializing in the research and development and production of specialized vehicles, has leveraged its qualifications under China's "Announcement of Automotive Manufacturing Enterprises and Products" and "3C" compulsory certification. The company not only specializes in the research and development and manufacture of various heavy-duty trailers, but also continuously innovates in advanced technologies such as multi-axle steering, hydraulic suspension, and powered goosenecks, offering customers a full range of products, including the SPMT.

Fundamental Differences in Structural Design

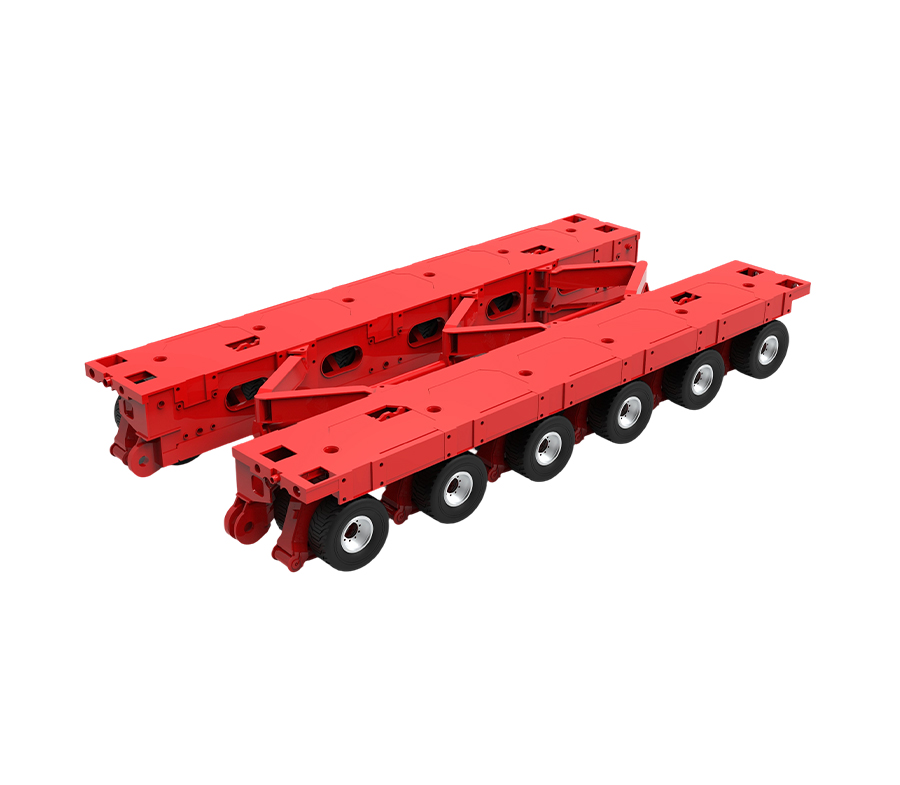

Standard flatbed trailers primarily feature a fixed or retractable frame, are typically monocoque, and are powered by a tractor. Their design focuses on load-bearing capacity and platform stability, making them suitable for road transport of medium-to-large cargo such as containers, construction components, and machinery. The International SPMT utilizes a modular design, with each module consisting of multiple axes and equipped with an independent hydraulic system and control unit. Modules can be arranged longitudinally, transversely, or in a matrix configuration to accommodate cargo of varying sizes and weights. For example, when transporting modules for bridges, ship hulls, and offshore drilling platforms weighing over 5,000 tons, the SPMT can create an ultra-large load platform by connecting multiple modules in parallel. This structural flexibility is unattainable with conventional flatbed trailers.

In Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s product line, the SPMT modular trailer utilizes a high-strength alloy steel structure and a precision hydraulic suspension design, enabling ±300mm lift adjustment to adapt to complex terrain while maintaining load platform stability.

Technological Differences in Drive and Control Systems

Conventional flatbed trailers rely on the tractor's engine and transmission system, using centralized drive. Steering typically utilizes a gooseneck or tractor-controlled system, limiting maneuverability. The SPMT is fully driven and self-propelled. Each wheel is driven by an independent hydraulic motor and synchronized by a computer, enabling 360° steering (e.g., crab-walking, lateral movement, and diagonal movement). This design enables the SPMT to transport oversized loads in confined spaces without requiring turning radius restrictions.

Kotter's SPMT utilizes internationally advanced multi-axle steering technology and a wireless remote control system, allowing operators to control the speed, steering, and posture of each module in real time, significantly improving transport flexibility and safety.

Operating Capacity and Load Range

The load capacity of a single conventional flatbed trailer typically ranges from tens to hundreds of tons. When exceeding this limit, multiple trailers must be transported in parallel or in series, which is inefficient and subject to road conditions.

The SPMT's single-axle load capacity can reach 30-45 tons, and this capacity can be expanded to thousands or even tens of thousands of tons through multi-axle combinations. In large-scale projects, such as transporting nuclear power plant reactors, aerospace components, and offshore platform modules, the SPMT can be transported as a whole without disassembling the load, significantly reducing lifting and assembly time. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s SPMT modular vehicle can be flexibly configured with axles based on customer needs and can be interconnected with modules from major international brands, enabling cross-brand collaboration.

Applicable Scenarios and Industry Coverage

Conventional flatbed trailers are widely used on roads, at ports, and for some short-distance transshipment, suitable for transporting standardized or semi-standardized cargo.

SPMT applications are more focused on handling oversized, heavy, and non-standardized equipment, such as:

Offshore oil platform modules

Large dock hull sections

Overall bridge installation

Wind turbine towers and nacelles

Large chemical reactors and storage tanks

In these areas, SPMTs can accomplish heavy-load transport across terrain and regions, tasks that conventional flatbed trailers cannot.

Safety and Redundancy

Conventional flatbed trailers use relatively simple methods for securing cargo during transportation, primarily relying on lashings and brackets. Their ability to resist overturning depends on road conditions and driver skill. The SPMT's hydraulic suspension system incorporates an automatic balancing function, allowing real-time adjustment of load distribution between wheels. This ensures a level platform even on uneven surfaces or with uneven loads, preventing structural stress concentration. Furthermore, the SPMT's redundant power system and multiple control signals ensure safe evacuation in the event of a local system failure.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has incorporated multi-level hydraulic circuit redundancy, electronic tilt sensors, and a load monitoring system into the SPMT's safety design to ensure stable and safe transport of overweight cargo.

How does the international SPMT's power system achieve self-propulsion?

Power Source: The Core Advantage of Independent Drive Units

The core of the SPMT's self-propulsion lies in the fact that each module is equipped with an independent power pack unit (PPU). The PPU typically contains a diesel engine or electric motor, a hydraulic pump assembly, a cooling system, and control electronics. It uses hydraulic fluid to drive the hydraulic motors of each wheel, achieving independent propulsion.

Diesel hydraulic system: A traditional mainstream solution with stable power output suitable for long-term, high-load operation.

Electric hydraulic system: Low noise and emissions, making it more suitable for urban or environmentally stringent project sites. In Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s SPMT products, the PPU utilizes engines and hydraulic pumps from internationally renowned brands. Combined with the company's independently developed energy efficiency optimization system, it automatically adjusts output power based on load and operating mode, reducing fuel consumption and extending equipment life.

Hydraulic Drive: Every Wheel is a Power Source

Each wheel set of the SPMT (usually four wheels per set) is equipped with a hydraulic drive motor and independent suspension system. The engine's mechanical energy is converted into high-pressure hydraulic oil by the hydraulic pump and then distributed through distribution valves to the hydraulic motors of each wheel set, achieving balanced drive.

The advantages of this design include:

Full-drive capability: Even if some wheels encounter low-friction surfaces, the remaining wheels still provide sufficient traction.

Precise speed control: The hydraulic system offers stepless speed regulation, achieving millimeter-level displacement accuracy.

High load adaptability: The hydraulic drive can withstand instantaneous high torque output, meeting the requirements of starting and climbing heavy loads. Kotter's SPMT incorporates proportional control valves and electronic synchronization modules in its hydraulic system, ensuring perfect synchronization between hundreds of wheels. This ensures a stable cargo position even during curves and lateral maneuvers.

Control Method: Omnidirectional Maneuverability and Precision Positioning

The SPMT's self-driving capabilities are not only reflected in its ability to "move on its own," but more importantly, its ability to "move as desired." Its control system utilizes Electronic Multi-Axle Steering & Drive Control technology to precisely match the drive and steering angles of each wheel set, enabling the following driving modes:

Straight Mode: All wheels drive in the same direction, suitable for long-distance travel.

Crab Mode: All wheels steer in parallel, enabling lateral movement.

Oblique Mode: Synchronized movement at a specific angle, suitable for maneuvering around obstacles in narrow workspaces.

In-Place Rotation Mode: The left and right wheels drive in opposite directions, allowing for rotating large cargo in place. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s SPMTs are equipped with a wireless remote control system and a wired backup console, allowing operators to monitor and control the vehicle in real time from a safe distance. The system also records every operating parameter for subsequent maintenance and operational optimization.

Energy Management: Equally Prioritizing Efficiency and Environmental Protection

International large-scale engineering projects are placing increasing demands on equipment energy efficiency and environmental protection, and the SPMT's power system is constantly being upgraded.

Intelligent Load Control: Dynamically distributes hydraulic pump output based on load and travel speed, reducing no-load energy consumption.

Idle Speed Optimization: When waiting for work or making slow adjustments, the system automatically reduces engine speed to reduce fuel consumption and noise.

Hybrid Solution: Some advanced SPMTs incorporate battery packs for auxiliary power, making them suitable for operation indoors or in environmentally sensitive areas.

Kotter's energy management integrates digital control and energy-saving hydraulic modules to significantly reduce operating fuel consumption while ensuring power redundancy, thereby lowering operating costs for customers and improving their environmental image.

What are the main safety risks when operating an SPMT?

Overloading and Uneven Load Distribution

Risk Description:

Although the SPMT has a single-axle load capacity of 30-45 tons, in actual operation, if the cargo weight exceeds the total load capacity of the module assembly or the load is unevenly distributed, this can cause overload on the hydraulic suspension, structural deformation, or even overturning.

Preventative Measures:

Perform accurate load calculations and simulation analysis before operation.

Use the Kotter load monitoring system to monitor the load on each axle in real time to prevent overloading.

Ensure that the cargo's center of gravity is as close as possible to the geometric center of the SPMT module.

Insufficient Ground Bearing Capacity and Fluctuating Road Conditions

Risk Description:

During movement, the SPMT exerts significant pressure on the ground from a single wheel. If the foundation bearing capacity is insufficient or there are settlements or soft areas on the road surface, the equipment may become stuck or tilt.

Preventative Measures:

Inspect and reinforce the foundation bearing capacity during the operation planning phase.

Kotter's construction guidelines recommend laying steel plates or reinforcing cushioning layers on weak road surfaces. A hydraulic suspension automatic balancing system is used to minimize the impact of uneven road surfaces on the platform's posture.

Steering and Synchronous Control Errors

Risk Description:

The SPMT's omnidirectional steering system requires the synchronized operation of multiple wheel sets. Any steering anomaly or control signal delay in any wheel set could cause the platform to deviate, increasing the risk of collision between the cargo and surrounding obstacles.

Preventative Measures:

Test the steering and drive functions of all wheel sets before operation.

Kotter's SPMT utilizes an electronic multi-axis synchronous control system and redundant signal lines to minimize the probability of control failures.

Operators must be trained in the system's steering modes (straight ahead, crab maneuver, diagonal maneuver, pivoting on the spot, etc.).

Climate and Environmental Factors

Risk Description:

High winds, heavy rain, low temperatures, high temperatures, and highly corrosive environments can affect the safe operation of the SPMT. For example, strong winds can create additional overturning moments on cargo with a high center of gravity, and low temperatures can reduce the fluidity of the hydraulic oil.

Preventative Measures:

Establish operating restrictions for weather conditions, such as suspending operations if wind speeds exceed a safety threshold. The hydraulic system provided by Kotter supports low-temperature hydraulic oil and is equipped with a preheating function to adapt to extremely cold operating environments.

In high-temperature or dusty conditions, strengthen the protection and maintenance of the hydraulic and electrical control systems.

Personnel Misoperation and Poor Communication

Risk Description:

SPMT operations often involve multiple operators (remote control, ground control, monitoring, etc.). Any miscommunication or operational errors can lead to accidents.

Preventative Measures:

Utilize the dual-channel communication system provided by Kotter to ensure real-time transmission of operating instructions and feedback information.

Establish standardized hand gestures, intercom, and signaling procedures to avoid command confusion.

Strictly implement personnel certification and regular training systems.

Equipment Failure and Improper Maintenance

Risk Description:

Failure to promptly detect problems such as hydraulic leaks, drive motor failure, and control unit malfunction can lead to sudden loss of control or shutdown during operation.

Preventative Measures:

Perform routine inspections and maintenance according to the equipment maintenance schedule established by Kotter.

Install a real-time fault diagnostic system on the SPMT to provide early warning of potential problems. Ensure that key components (hydraulic pumps, valve groups, sensors, etc.) have spare inventory to reduce maintenance time.

English

English  中文简体

中文简体