-

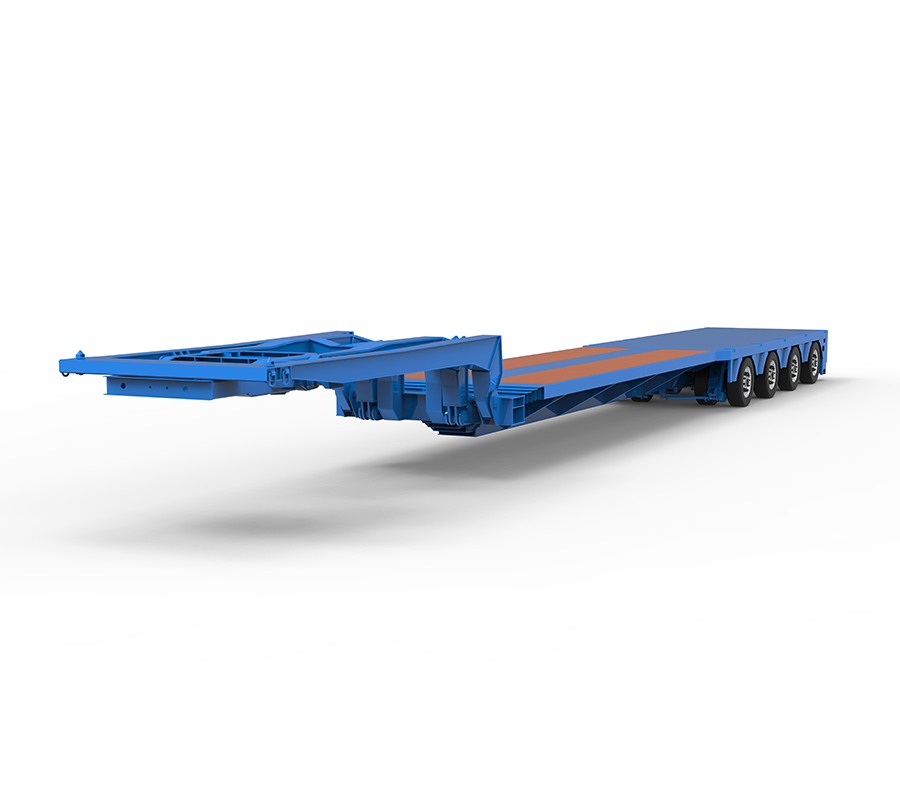

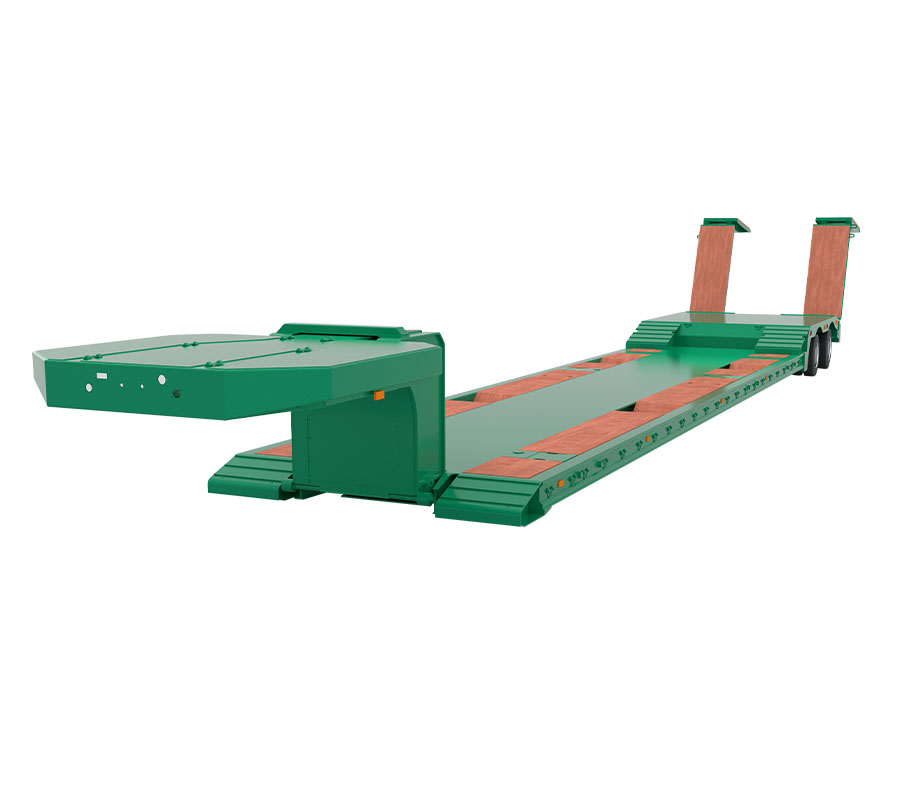

The Adjustable Gooseneck Low Flatbed Semi-Trailer has emerged as a game-changing solution for industries that rely on transporting oversized or heavy equipment....

READ MORE -

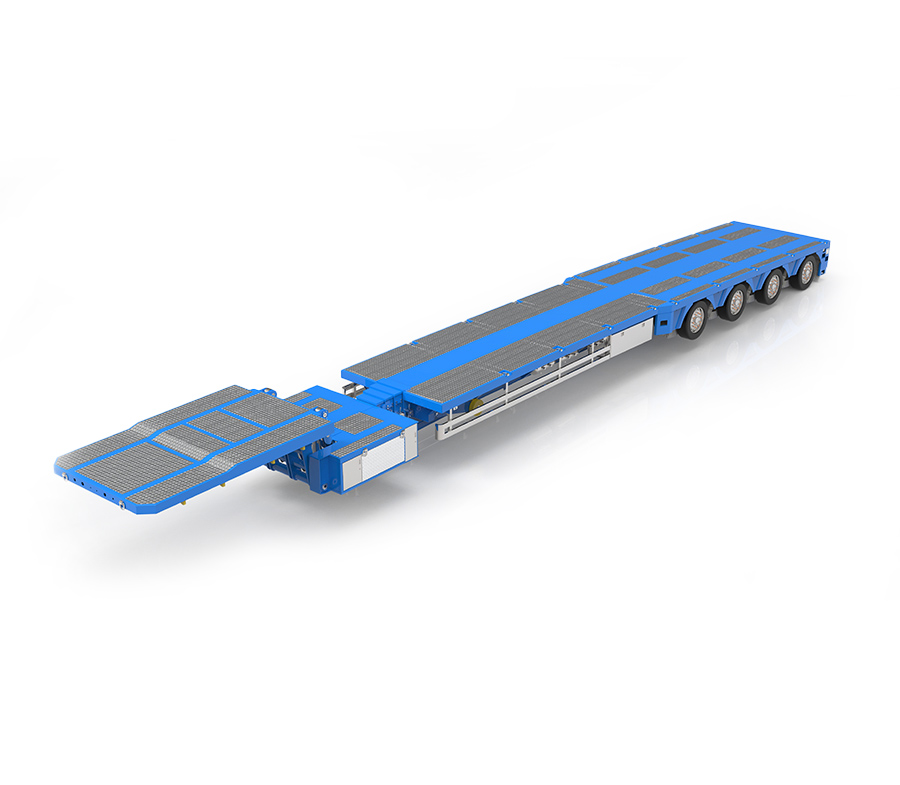

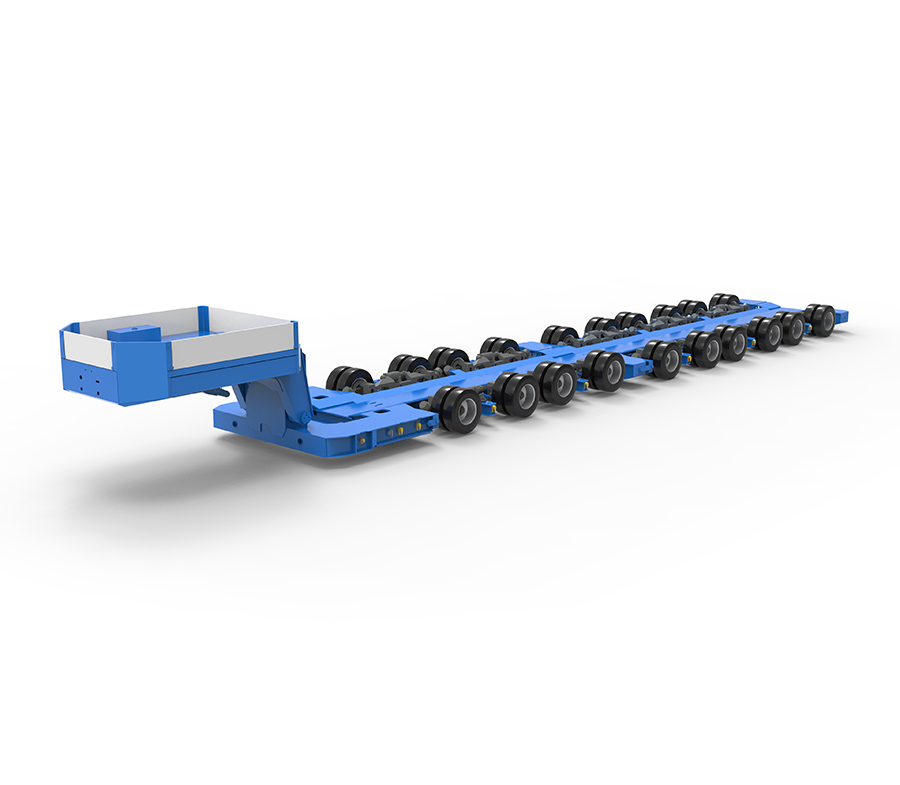

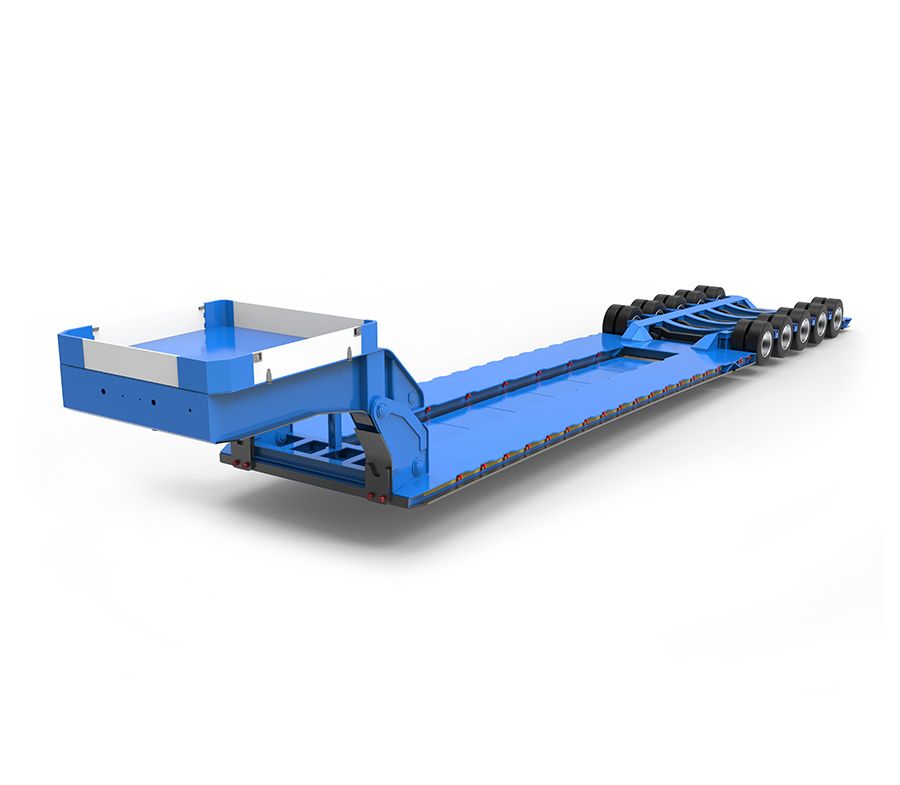

In the world of modern logistics and heavy cargo transportation, efficiency, stability, and adaptability are key. The KTG-4 hydraulic axles line trailer with 4 ...

READ MORE -

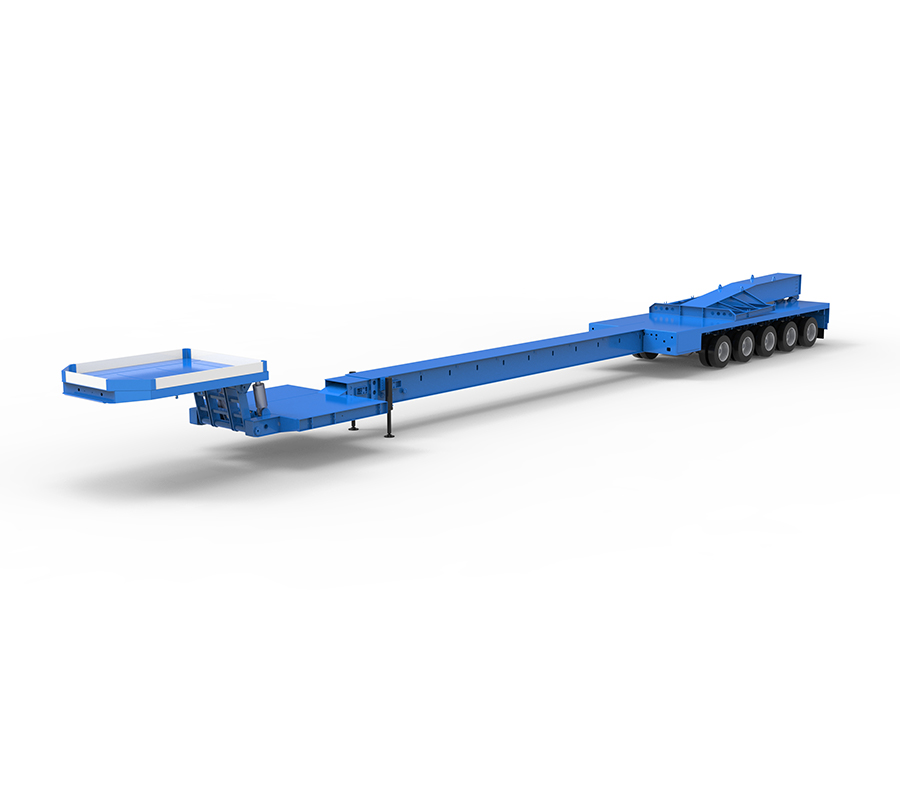

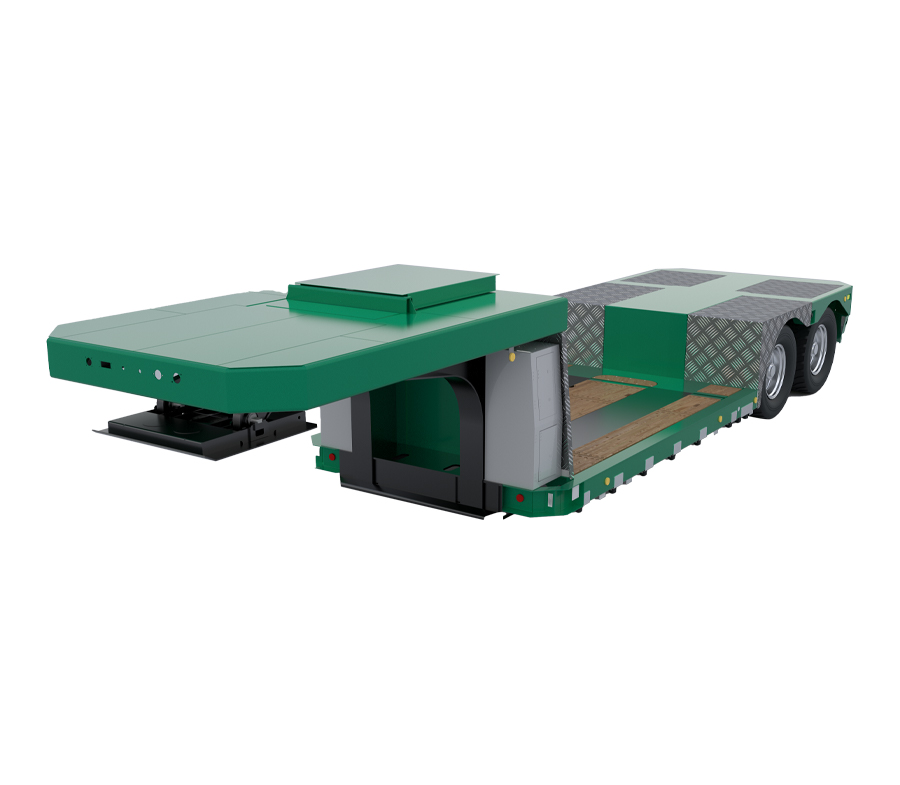

Precision Engineering and Stability: The Core of the Low Flatbed Precision Instrument Transport Semi-Trailer At the heart of the Low Flatbed Precision Instrumen...

READ MORE -

What Is a Wind Turbine Tower Bridge and Why Is It Essential? The Wind Turbine Tower Bridge is a specialized structural device used during the assembly of wind t...

READ MORE -

How Wind Turbine Tower Transport Semi-Trailer Improves Efficiency in Renewable Energy Logistics As the renewable energy industry continues to expand globally, t...

READ MORE

What are the main components of a semitrailer? What is the function of each part?

Semitrailers are specialized vehicles widely used for transporting heavy cargo. Their structure and design directly impact transport efficiency and safety. Hangzhou Kotter Intelligent Manufacturing Co., Ltd., a company specializing in the research and development and production of specialized vehicles, leverages its extensive experience and technological expertise to provide global customers with a wide range of high-tech heavy-duty semitrailers, including hydraulic axle semitrailers and SPMT modular transporters. Through the precise design and manufacturing of semitrailers, Kotter is committed to providing customers with high-quality and safe transportation solutions.

Chassis

The chassis is one of the core components of a semitrailer. Its design directly determines its load-bearing capacity, stability, and safety. The chassis is typically constructed of high-strength steel to ensure it can withstand the pressure of heavy loads during transport. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semitrailer frames utilize advanced welding technology and materials, ensuring they maintain a sturdy structure in harsh environments (such as high temperatures and dusty conditions) and resist deformation or damage.

The chassis' primary function is to support other components, particularly the wheels, axles, suspension system, and cargo. Its design also needs to take road suitability into consideration. Frame durability is crucial, especially in the challenging terrain of regions like the Middle East.

Suspension System

The suspension system is the primary component of a semi-trailer that contacts the ground, ensuring vehicle stability, balance, and comfort. During transport, the suspension system helps reduce vibrations and absorb road impacts, ensuring the cargo arrives safely and smoothly at its destination. Common suspension systems include air suspension, hydraulic suspension, and spring suspension.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers are available with optional hydraulic and air suspension systems. These systems are adjustable, allowing for optimal driving experience and stability based on varying road conditions. In hot, dusty environments like those in the Middle East, hydraulic suspension effectively improves vehicle stability and load-bearing capacity, making it particularly suitable for transporting heavy cargo.

Wheels and Axles

Wheels and axles are key components of a semi-trailer's load-bearing capacity. Depending on the load requirements, a semi-trailer can be equipped with varying numbers of axles, typically single, dual, or multiple. Axle design must consider the weight distribution of the cargo to ensure even load distribution, thereby improving transportation safety and efficiency.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailer products feature technologies such as multi-axle steering and hydraulic axles, which effectively optimize vehicle maneuverability and load-carrying capacity, especially when transporting overweight or overlong cargo. These innovative technologies allow for more flexible steering, reduce transport route requirements, and significantly improve transport efficiency.

Brake System

The brake system is a key component of semi-trailer safety. Semi-trailers are typically equipped with pneumatic brakes, while some higher-end models may feature an electronic braking system (EBS) or other advanced braking technologies. The brake system not only provides sufficient braking force in emergency stops but also maintains stability during long transport periods to avoid the risk of brake failure.

In the complex environments of hot desert regions, such as those in the Middle East, the heat resistance of the brake system is particularly important. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers undergo rigorous testing to ensure excellent braking performance in extreme heat conditions, ensuring safe cargo transportation. 5. Kingpin and Fifth Wheel

The kingpin is a key component connecting the trailer to the tractor. Generally, it consists of the fifth wheel at the front of the vehicle and the hitch on the semi-trailer. The stability of the kingpin directly impacts the semi-trailer's maneuverability and safety.

Kotter's semi-trailers are equipped with high-strength kingpins, ensuring robust stability and durability even in extreme conditions. Especially when transporting heavy loads, the kingpin effectively transmits power, ensuring balance and stability.

Electrical System and Lighting

The electrical system and lighting primarily provide power and illumination for the vehicle, ensuring safe operation at night or in low-visibility conditions. Common electrical systems include onboard batteries, headlights, and signal lights. A sound electrical system is crucial for the operation of a semi-trailer, especially during long, heavy-duty hauls.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers are equipped with energy-efficient LED lighting, ensuring adequate illumination in all conditions. The electrical system also includes an intelligent monitoring system for real-time monitoring of the vehicle's operating status, reducing malfunctions and improving transport safety and reliability.

Cargo Securing Equipment

Cargo securing equipment, including cargo straps, supports, and locks, is critical for securing cargo during transport. Effective cargo securing equipment not only improves transport efficiency but also prevents accidents caused by cargo sliding or falling.

Kote's semi-trailer designs incorporate a variety of cargo securing solutions suitable for various types of cargo, such as wind turbine blades and heavy machinery. These securing devices ensure cargo remains secure during long-distance transport, effectively improving transport safety and reliability.

What are the special requirements for semi-trailer weight limits and transportation regulations in the Middle East?

The Middle East's geographical environment, climate, and transportation needs lead to unique requirements for semi-trailer weight limits and transportation regulations. As a specialized vehicle R&D and manufacturing company, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has a deep understanding of these needs and offers a variety of heavy-duty semi-trailer products, including high-tech heavy-duty hydraulic axle semi-trailers and SPMT modular transporters, to meet the demand for high-performance transport equipment in the Middle East and global markets.

Semi-trailer Weight Limits in the Middle East

In the Middle East, semi-trailer weight limits are often influenced by multiple factors, including road infrastructure, climatic conditions, and specific laws and regulations in different countries. Each country has strict regulations on transport weights and dimensions to ensure road safety, avoid traffic congestion, and protect transportation facilities.

Road Infrastructure

Road conditions in the Middle East vary, ranging from modern highways and urban streets to rugged desert and mountainous roads. These varying road conditions place varying demands on the load capacity of semi-trailers. Generally speaking, modern highways and expressways can carry larger loads, while roads in mountainous and desert regions, due to insufficient infrastructure, limit the maximum load capacity of vehicles. 1.2 Climate Conditions

The Middle East's hot climate, especially summer temperatures, can affect a middle east semitrailer's load capacity. High temperatures can easily cause tires to overheat, which in turn affects the performance of axles and braking systems. Therefore, when designing semitrailers, special consideration must be given to climate factors to ensure safety and reliability in high-temperature environments. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s extensive experience in this area enables the company to provide semitrailers suitable for extreme environments, utilizing high-temperature-resistant materials and optimized braking systems to ensure stable operation in high temperatures.

Regulations and Weight Limits

Weight limits for semitrailers vary from country to country, but are generally determined by vehicle type, number of axles, tire specifications, and other factors. For example, the UAE has a maximum permissible weight of 40 tons, while certain regions of Saudi Arabia have strict restrictions on the transport of cargo exceeding 50 tons. When designing semitrailers for the Middle Eastern market, the team at Hangzhou Kotter Intelligent Manufacturing Co., Ltd. ensures that each product meets local weight and size requirements, helping customers avoid legal issues and transportation accidents caused by overloading.

Transport Regulations in the Middle East

Transport regulations in the Middle East primarily cover vehicle dimensions, transport permits, driver requirements, and other aspects. Understanding and adhering to these regulations is crucial to ensuring smooth transport operations.

Vehicle Dimension Restrictions

Similar to weight restrictions, semi-trailer dimensions are also strictly regulated. The width, height, and turning radius of roads, bridges, and tunnels limit transport vehicle size. Many older urban areas in the Middle East feature narrow roads and limited bridge heights, requiring semi-trailer designs to fully account for these limitations. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers, particularly those with variable wheelbases and hydraulic axles, allow for flexible vehicle dimensions to adapt to varying road conditions, ensuring smooth transport operations in complex road conditions.

Special Transport Permits

Since semi-trailers are often used to transport overweight, overlong, or unusually shaped cargo, such as wind turbine blades and construction machinery, many Middle Eastern countries require special transport permits for these cargoes. For example, the UAE and Saudi Arabia have additional permit requirements for transporting cargo exceeding certain weights or dimensions. These permits typically require advance application and include approval of transport routes and arrangements for road closures. To ensure these processes run smoothly, Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s engineering team provides professional consulting services to help customers ensure transport operations are carried out within the required framework.

Driver and Operating Requirements

The Middle East has high driver qualification requirements, especially for heavy and long hauls. Transporting heavy cargo requires not only an advanced driver's license but also specialized training to master critical skills such as operating hydraulic systems, adjusting vehicle loads, and controlling brakes. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers are equipped with advanced hydraulic systems and multi-axle steering technology, which require specialized driver skills to operate safely. Therefore, the company provides customers with relevant training and technical support to ensure that drivers are able to operate these high-tech equipment safely and proficiently.

Safety Standards and Inspections

Safety standards for semi-trailers are particularly important in the Middle East. Since the loads transported often reach extreme limits, any system failure could lead to serious accidents. Therefore, many countries require regular inspections of all parts of semi-trailers, including brakes, tires, and suspension systems. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailers undergo rigorous quality control and testing to ensure they meet international safety standards before leaving the factory. Furthermore, the company provides regular maintenance and inspection services to ensure the long-term operational safety of its products.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Solutions

As a company specializing in the research and development and production of specialized vehicles, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. is well aware of the high standards required for transportation equipment in the Middle East. The company's high-tech hydraulic axle semi-trailers, multi-axle steering semi-trailers, and SPMT modular transporters are meticulously designed to withstand the Middle East's extreme climate, complex road conditions, and strict transportation regulations.

Features of the company's products include:

Multi-axle steering technology: Adapts to diverse road conditions, especially for efficient operation in narrow city streets or complex terrain.

Hydraulic suspension system: Effectively reduces vibration, ensuring smooth transport of heavy cargo, especially in the desert environments of the Middle East. High-strength frame design: Utilizing high-temperature and corrosion-resistant materials, it's engineered to withstand the high temperatures and dusty environments of the Middle East.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. not only provides semi-trailers that comply with Middle Eastern regulations but also offers customized services based on specific customer needs, ensuring each product maximizes transportation efficiency and minimizes operating costs.

How to Achieve Effective Load Balancing on Semi-trailers to Ensure Transport Safety on the Harsh Roads of the Middle East

The Importance of Load Balancing

Load balancing refers to the proper distribution of load among a semi-trailer's axles, ensuring that each axle's load remains within the permitted range, thereby improving vehicle stability and safety. Uneven load distribution can lead to axle overload, suspension failure, excessive tire wear, and even vehicle loss of control or damage. Load balancing is crucial for transport safety, particularly in the Middle East, where some roads are rugged and lack essential transportation facilities.

How to Achieve Load Balancing on Semi-trailers

Multi-Axle System Design

In semi-trailer design, the use of a multi-axle system effectively distributes weight and reduces the load pressure on a single axle. By carrying cargo across multiple axles, a multi-axle system ensures that the weight borne by each axle does not exceed its designed load, thereby avoiding vehicle damage and safety hazards caused by overloading.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. provides multi-axle steering systems and adjustable wheelbase designs, allowing semi-trailers to be flexibly adjusted to the weight and size of the cargo being transported. Especially when transporting overweight or unusually shaped cargo, the multi-axle design maximizes load balance, ensuring even load distribution across each axle.

Hydraulic Suspension System

The hydraulic suspension system automatically adjusts vehicle height and load distribution, effectively reducing vibration and maintaining vehicle stability on uneven roads. The desert and mountainous terrain of the Middle East places higher demands on the semi-trailer's suspension system, especially in high temperatures and dusty environments. Conventional steel spring suspension systems often lack sufficient stability.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s hydraulic suspension system adjusts suspension stiffness and height in real time based on the load, optimizing vehicle balance and reducing impact on various vehicle components. The hydraulic system also reduces vibration, ensuring cargo stability during transport, especially on the rugged roads and high temperatures of the Middle East, where hydraulic suspension provides additional protection.

Adjustable Wheelbase Design

Adjustable wheelbase is another important technology for load balancing, particularly suitable for complex transport tasks in the Middle East. The adjustable wheelbase system allows the distance between the semi-trailers to be adjusted according to the characteristics of the cargo being transported, optimizing load distribution. When transporting extra-long and heavy cargo, proper wheelbase adjustment can prevent vehicle tilt or instability caused by uneven loading.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailer products include a variable wheelbase design that can accommodate the transport needs of cargo of varying sizes. This design allows for more even load distribution, ensuring that the weight carried by each axle remains within a safe range, especially when transporting specialized cargo such as large machinery or wind turbine blades.

Dynamic Load Monitoring System

Dynamic load monitoring systems are an advanced technology that has been gradually adopted in semi-trailers in recent years. They monitor the load on each axle in real time and provide feedback to the driver via an onboard computer or mobile device. When the load on an axle exceeds a set safety threshold, the system issues an alarm, prompting the driver to adjust the load or take other safety measures. This technology is crucial for ensuring the transport of heavy cargo in complex environments such as the Middle East.

Ensuring Transportation Safety on Harsh Roads in the Middle East

Impact of High Temperatures and Dust on Load Balancing

The high temperatures and dust storms in the Middle East place special demands on load balancing on semi-trailers. High temperatures can cause tire temperatures to rise, compromising the stability of axles and braking systems. Furthermore, sandstorms can cause slippery roads, making transport more difficult. In such conditions, uneven loading can exacerbate these problems and lead to the risk of accidents.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s semi-trailer designs take these extreme climate factors into account. The company utilizes heat-resistant and corrosion-resistant materials, along with a high-quality braking system, to ensure stable operation even in high temperatures and dusty conditions. Furthermore, hydraulic suspension and an adjustable wheelbase system provide enhanced stability on uneven desert or mountain roads, effectively distributing the load and preventing structural damage caused by concentrated loads.

The Relationship Between Road Conditions and Load Balancing

Road conditions in the Middle East are complex, ranging from highways to desert sections. These diverse road conditions require semi-trailers to be adaptable. Especially on uneven and bumpy roads, vehicles may experience severe vibrations and irregular slopes, all of which directly impact load balance. Conventional semi-trailers can easily lose stability in such conditions, and high, uneven loading can exacerbate these problems. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes an advanced suspension system and multi-axle design to ensure vehicle stability in diverse road conditions. Especially on uneven desert or mountainous terrain, the hydraulic system automatically adjusts the suspension height to effectively absorb shock, reducing the burden on the axles and maintaining smooth operation.

English

English  中文简体

中文简体