-

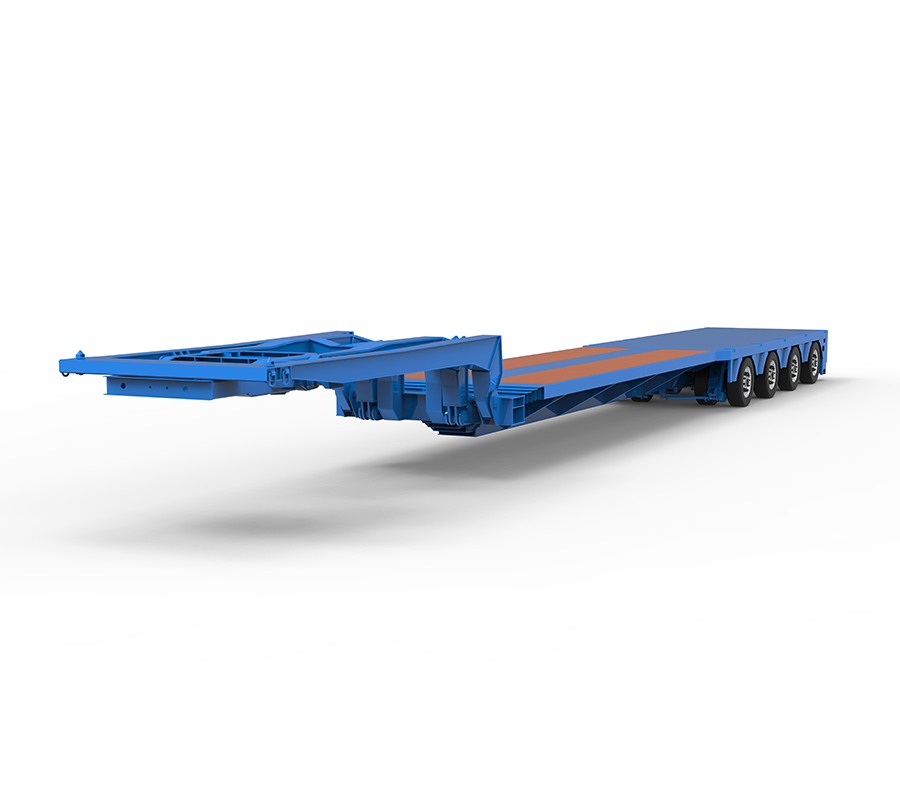

The Adjustable Gooseneck Low Flatbed Semi-Trailer has emerged as a game-changing solution for industries that rely on transporting oversized or heavy equipment....

READ MORE -

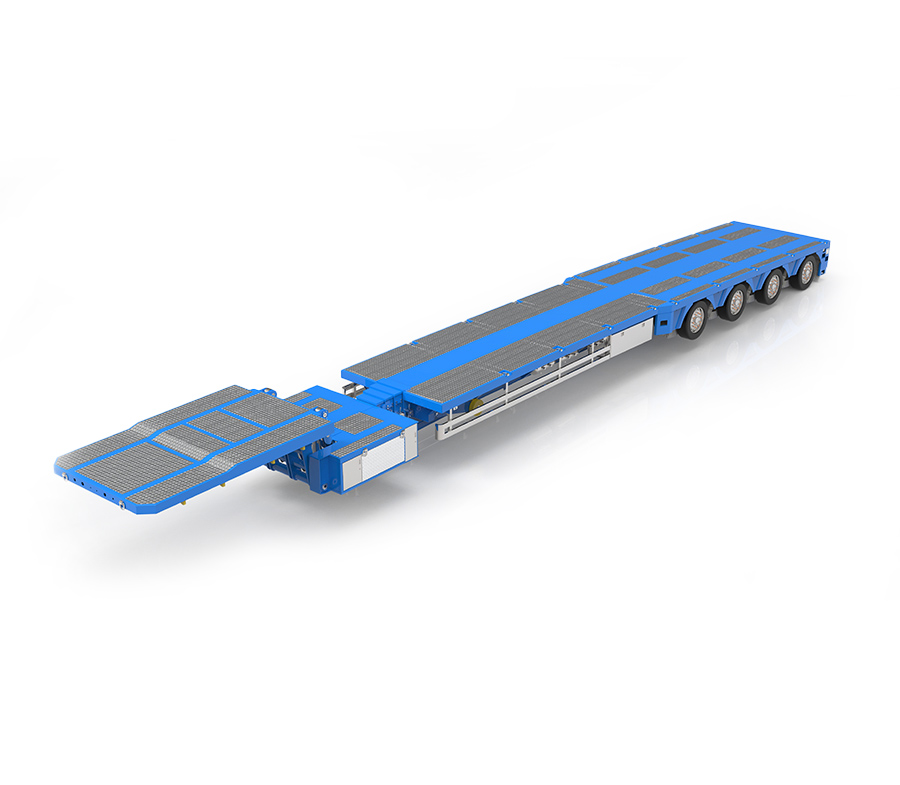

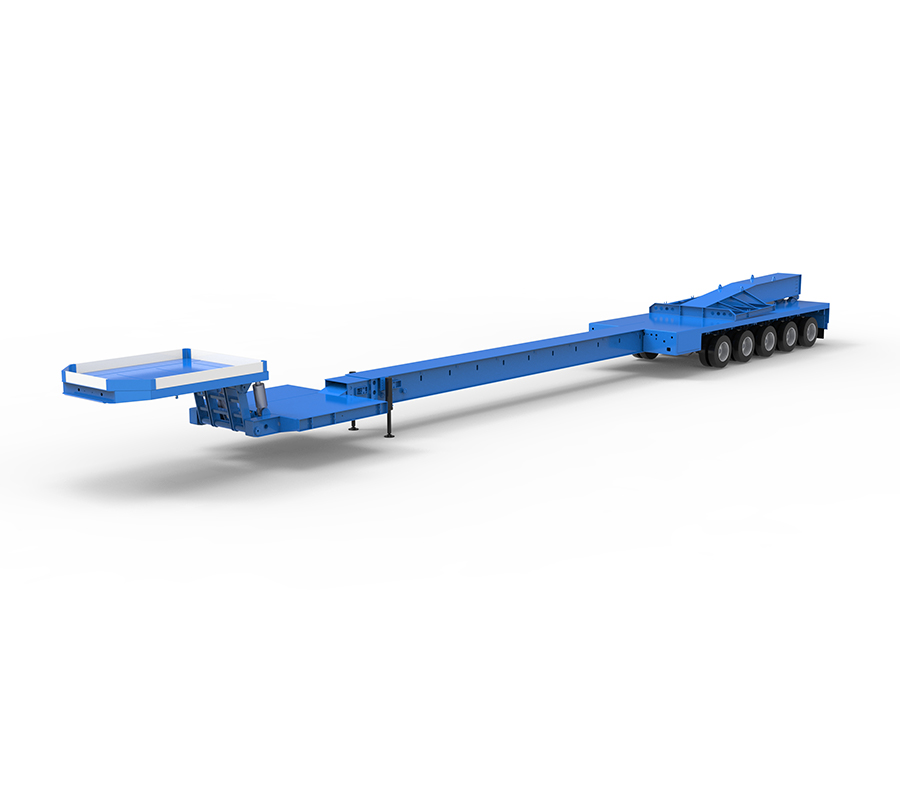

In the world of modern logistics and heavy cargo transportation, efficiency, stability, and adaptability are key. The KTG-4 hydraulic axles line trailer with 4 ...

READ MORE -

Precision Engineering and Stability: The Core of the Low Flatbed Precision Instrument Transport Semi-Trailer At the heart of the Low Flatbed Precision Instrumen...

READ MORE -

What Is a Wind Turbine Tower Bridge and Why Is It Essential? The Wind Turbine Tower Bridge is a specialized structural device used during the assembly of wind t...

READ MORE -

How Wind Turbine Tower Transport Semi-Trailer Improves Efficiency in Renewable Energy Logistics As the renewable energy industry continues to expand globally, t...

READ MORE

What is the difference between a flatbed semi-trailer and an enclosed semi-trailer?

In the heavy-duty transport sector, flatbed semi-trailers and enclosed semi-trailers are two common modes of transport. Each has unique design and features, suiting different transportation needs. In this field, Hangzhou Kotter Intelligent Manufacturing Co., Ltd., a company specializing in the research and development and production of specialized vehicles, is committed to providing a variety of heavy-duty trailer solutions, including flatbed and enclosed semi-trailers.

Differences in Design and Structure

The flatbed semi-trailer's design is characterized by its flat body, lacking a protective structure. Typically constructed of steel or aluminum alloy, it offers a strong load-bearing capacity. The body lacks any enclosed space above it, and cargo is placed directly on the body. Common cargo, such as construction materials, steel, large machinery, and containers, requires external securing equipment for safe transportation. The flatbed semi-trailer's design offers greater loading and unloading flexibility, making it suitable for transporting items that are sensitive to weather or inherently pressure-resistant. In contrast, a closed semi-trailer features a fully enclosed cargo compartment, typically equipped with sturdy sidewalls and a roof, ensuring better protection during transport. Closed semi-trailers are typically used to transport goods that require protection from rain, wind, dust, and other hazards, such as electronics, food, and valuables. Designed for enhanced safety and confidentiality, they are more suitable for transporting environmentally sensitive goods.

Different Application Scenarios

Flatbed semi-trailers are suitable for transporting large and heavy goods that are less environmentally sensitive. For example, heavy or bulky items such as construction machinery, steel, and wind turbine blades offer significant advantages, especially when loading and unloading in open spaces or specialized areas. The lack of an enclosed compartment makes loading and unloading more convenient, and reduces the need to consider interior space constraints.

Closed semi-trailers are primarily used to transport items that are more sensitive to the external environment, such as precision instruments, household appliances, medical supplies, and food. During transportation, these goods need to be protected from external environmental factors such as moisture, dust, and temperature fluctuations. The enclosed semi-trailer design provides enhanced protection, ensuring the goods remain intact during transport.

Transport Efficiency and Safety

In terms of transport efficiency, the advantage of flatbed semi-trailers lies primarily in the ease of loading and unloading. Because they lack an enclosure, cargo can be placed directly onto the trailer bed through hoisting or stacking, resulting in faster loading and unloading operations. This is particularly important for transporting bulk cargo that requires frequent loading and unloading. Because flatbed semi-trailers typically have a low chassis height and a high load capacity, they are ideal for transporting heavy cargo that requires a low floor.

Enclosed semi-trailers offer greater transport security, especially when transporting valuable goods or goods with strict temperature and humidity requirements. The enclosed bed effectively protects cargo from the elements, minimizing damage and quality issues. Furthermore, the enclosed design prevents theft and other external interference. Therefore, enclosed semi-trailers are clearly the preferred choice for high-value, fragile, or confidential cargo. 4. Adaptability to Different Terrains and Climates

Another outstanding feature of flatbed semi-trailers is their adaptability to various complex terrains. This is particularly true when transporting goods through remote areas or areas without well-developed infrastructure. Flatbed semi-trailers often incorporate advanced technologies such as multi-axle axles and hydraulic suspension, enabling them to flexibly adapt to varying road conditions and load requirements. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s heavy-duty hydraulic axle semi-trailers were developed specifically with this in mind, providing excellent traction and stability in a variety of complex transport environments.

Enclosed semi-trailers, on the other hand, prioritize climate control and protection. In extreme weather conditions, the enclosed compartment effectively shields cargo from external heat and cold, rain, and snow, ensuring their safety. Enclosed semi-trailers are particularly indispensable in cold chain transportation.

What types of tires are commonly used on flatbed semi-trailers?

Basic Requirements for Flatbed Semi-trailer Tires

As a vehicle used for long-distance transportation and carrying heavy cargo, flatbed semi-trailers must meet the following basic requirements for their tires:

High load capacity: Since flatbed semi-trailers often transport large quantities of heavy cargo, tire load capacity is crucial. Tires with insufficient load capacity can lead to unstable driving and even serious problems such as blowouts.

Strong wear resistance: Prolonged use and high loads require tires with strong wear resistance to extend their service life and maintain low operating costs.

Good grip: Flatbed semi-trailer tires must provide sufficient grip to ensure safe driving in various road conditions, especially on slippery or rough roads.

High temperature and high pressure tolerance: Prolonged high-speed driving or heavy load transportation can cause tire temperatures to rise. Tires must be able to withstand high temperatures and high pressures to avoid damage caused by overheating.

Common Flatbed Semi-Trailer Tire Types

Flatbed semi-trailers typically use the following types of tires. Choosing the right tire, depending on load requirements, transport routes, and operating environments, is crucial for ensuring safe and efficient transport.

Single and Dual Tires

Single tires: Single tires are typically used on flatbed semi-trailers with wider tire widths. Compared to dual tires, single tires offer lower installation costs, but they place higher load-carrying capacity and load requirements on the tires. Single tires are suitable for light and low-to-medium load transports.

Dual tires: Dual tires are a more common tire configuration on flatbed semi-trailers, particularly for heavy-duty transports. Dual tires offer greater load capacity, better distribute axle weight, reduce tire wear, and improve transport stability. Dual tires are widely used on flatbed semi-trailers that require extended high-speed travel and heavy loads, and are particularly suitable for transporting overweight or bulky cargo.

High-Load Tires

High-Load Tires on flatbed semi-trailers are designed for heavy loads and can support a higher weight per tire. Generally speaking, these tires feature thicker wall thickness and a more robust structural design, capable of carrying extremely high static and dynamic loads. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s high-tech, heavy-duty hydraulic axle semi-trailers utilize tires that meet high-load standards, ensuring vehicle stability and safety when transporting heavy machinery, construction materials, and other cargo.

Low-Pressure Tires

Low-pressure tires are also used in some specialized applications. These tires are characterized by lower inflation pressure, providing improved grip in harsh conditions such as soft soil, muddy roads, and deserts. Their larger contact patch distributes the vehicle's weight, reducing ground pressure, thereby improving maneuverability and stability. For missions requiring the transport of heavy equipment to remote locations, the advantages of low-pressure tires are significant.

Factors Influencing Tire Selection for Flatbed Semi-trailers

Selecting flatbed semi-trailer tires requires consideration of multiple factors, including but not limited to the weight of the cargo being transported, the distance being transported, the type of road, and weather conditions. When designing and producing heavy-duty trailers, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. always provides customized tire solutions based on specific customer needs to ensure efficient and safe transportation.

Weight of Transported Cargo

The tire's load capacity is directly related to the weight of the cargo being transported. For heavy-duty transport, such as transporting large equipment like construction machinery and wind turbine blades, tires must have a high load capacity. This requires tires designed to withstand the high pressure loads on each axle while maintaining stable driving performance. Hangzhou Kotter's hydraulic suspension system and multi-axle axle design provide the optimal tire solution for each transport mission.

Road Type and Transport Environment

The choice of tire for a flatbed semi-trailer is also influenced by the type of road being transported. If the transport route involves uneven or rugged terrain, it is particularly important to use tires that are wear-resistant and impact-resistant. When traveling on highways, tires with excellent high-speed stability and low rolling resistance are required to improve fuel efficiency and driving safety. Hangzhou Kotter's multi-axle steering system and hydro-pneumatic suspension system effectively reduce tire wear and extend tire life. 3.3 Climate and Environmental Conditions

The impact of climate conditions on tire performance cannot be ignored. High temperatures can cause excessive tire wear or blowouts, while low temperatures can harden tires, reducing grip. Choosing the right tire material and design is particularly important in extreme environments. Hangzhou Kotter's semi-trailer product line is equipped with tires tailored to the climate conditions of different regions, ensuring efficient transportation even in extreme climates.

What Factors Affect the Towing Performance of a Flatbed Semi-Trailer?

As a common heavy-duty transport vehicle, the towing performance of a flatbed semi-trailer is directly related to safety, efficiency, and fuel consumption during transportation. In practice, flatbed semi-trailers are often used to carry heavy or extra-long cargo, making towing performance particularly important. Multiple factors influence a flatbed semi-trailer's towing capacity, including vehicle design, suspension system, load configuration, and road conditions.

Vehicle Design and Structural Configuration

The overall design and structural configuration of a flatbed semi-trailer have a decisive impact on its towing performance. The following design factors are directly related to towing capacity:

Vehicle weight and load capacity: The heavier the vehicle, the higher the towing capacity required. The chassis, frame, and suspension system of a flatbed semi-trailer must be designed to support the vehicle's own weight and the weight of the cargo. Proper weight distribution and high load-carrying capacity are crucial during the design phase. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s heavy-duty hydraulic axle semi-trailers utilize an innovative hydraulic suspension system and multi-axle axle design, effectively distributing the vehicle's load and reducing the burden on the trailer during towing.

Axle Configuration: The number and layout of axles directly determine the load on the wheels and the friction with the ground during towing. A multi-axle configuration evenly distributes weight, improving towing stability and efficiency. Hangzhou Kotter's multi-axle axle design, combined with hydraulic adjustment and variable wheelbase technology, not only optimizes the vehicle's towing performance but also enhances stability and adaptability on complex roads.

Influence of the Suspension System

The suspension system is a key factor influencing the towing performance of a flatbed semi-trailer. It determines the vehicle's comfort, stability, and maneuverability in contact with the ground. Common suspension systems for flatbed semi-trailers include:

Steel Plate Suspension: Traditional steel plate suspension systems use leaf springs to support the vehicle body, offering advantages such as simple structure, durability, and high load-bearing capacity. Steel plate suspension systems are suitable for flatbed semi-trailers with heavy loads, ensuring a stable center of gravity during towing.

Air Suspension: Air suspension systems use air springs to adjust the vehicle's height, ensuring stable towing performance under varying load conditions. This system reduces impact with the ground, improving towing comfort and maneuverability, and is particularly suitable for heavy-duty cargo transport on long highways.

Hydraulic Suspension: Hydraulic suspension systems use hydraulic devices to adjust the height and stiffness of the vehicle body to adapt to varying loads and road conditions. This suspension system is commonly used on heavy-duty flatbed semi-trailers, such as the high-end hydraulic axle semi-trailers produced by Hangzhou Kotter. It provides more precise load control, improves towing performance, and reduces vehicle vibration in adverse road conditions, ensuring smooth transportation.

Tire and Axle Configuration

The traction performance of a flatbed semi-trailer is closely related to its tire and axle configuration. Appropriate tires not only provide better grip but also effectively reduce traction resistance.

Tire Type and Specification: Flatbed semi-trailers typically use high-load, wear-resistant tires to handle heavy-duty transports. Larger tires provide better stability and grip, especially on uneven surfaces, where tire grip and durability are crucial.

Axle Design: The number and configuration of axles affect the vehicle's traction force distribution. A sound axle design evenly distributes weight, reduces traction resistance, and improves stability. Hangzhou Kotter's hydraulically adjustable axle system offers significant advantages in this regard, allowing the height and angle of the axles to be adjusted according to actual needs, thereby improving the traction performance of the flatbed semi-trailer under varying loads.

Load Configuration and Cargo Type

The weight, shape, and distribution of the cargo directly impact the traction performance of a flatbed semi-trailer. For example, different types of cargo place varying demands on the center of gravity and total load of the flatbed semi-trailer. If the load is heavier at the front or rear of the vehicle, it may reduce vehicle stability during towing. Proper cargo distribution and lashing methods not only improve transport safety but also enhance the effectiveness of traction.

For overweight or long loads, Hangzhou Kotter's adjustable wheelbase design can help adjust the vehicle's center of gravity, optimizing load distribution during towing and ensuring smooth driving.

Road Conditions and Environmental Factors

The towing performance of a flatbed semi-trailer is also affected by road conditions and environmental factors. Complex road conditions (such as muddy, gravelly, and mountainous roads) can significantly challenge towing performance. In these situations, the adjustability of the suspension system, load distribution across the axles, and tire grip become particularly important.

Road Conditions: Rough roads and inclement weather require a towing system with greater adaptability. Hydraulic suspension systems and adjustable axle designs can adjust to actual road conditions, ensuring optimal towing performance in a variety of challenging conditions.

Environmental Factors: High or low temperatures, slippery roads, and snow can also affect the towing capacity of a flatbed semi-trailer. Especially in cold climates, tire grip and suspension responsiveness can be affected. Therefore, Hangzhou Kotter's product line includes flatbed semi-trailers designed for a variety of extreme environmental conditions, ensuring excellent performance in diverse climates.

Driving Techniques and Operation

The towing performance of a flatbed semi-trailer depends not only on the vehicle's design and configuration, but also on the driver's skill. Proper driving can reduce unnecessary traction resistance and improve vehicle stability and traction.

How do flatbed semi-trailers perform in different climates?

Performance in High Temperatures

In high temperatures, the towing performance, tires, and suspension systems of flatbed semi-trailers are put under greater pressure. High temperatures not only increase tire wear but can also degrade the performance of the vehicle's suspension, brake, and hydraulic systems. Hangzhou Kotter's hydraulic suspension system and multi-axle steering technology effectively reduce the burden on the vehicle in high temperatures, allowing the flatbed semi-trailer to maintain excellent traction and stability even under load.

Tire Performance: In high temperatures, tire rubber softens due to overheating, making it more susceptible to wear and even blowouts. To this end, Hangzhou Kotter prioritizes high-temperature resistance when selecting tires for its flatbed semi-trailers. Specialized high-temperature-resistant tires are used. These tires utilize advanced rubber compounds that maintain their shape in high-temperature conditions, preventing excessive expansion or softening, thereby extending tire life and traction stability.

Suspension System Adaptability: The suspension system of a flatbed semi-trailer requires enhanced stability in high temperatures to reduce vehicle vibration on bumpy roads. Hangzhou Kotter's air and hydraulic suspension systems excel in this regard, effectively reducing vehicle vibration and maintaining a smooth ride.

Performance in Cold Weather

The impact of cold weather on flatbed semi-trailers is primarily reflected in the negative effects of low temperatures on tires, hydraulic fluid, suspension, and brake systems. Cold temperatures cause tires to harden, reducing grip; hydraulic fluid viscosity increases, slowing hydraulic system response; and brake system failure due to ice. To address this, Hangzhou Kotter has implemented the following technological innovations to ensure its flatbed semi-trailers maintain excellent performance in cold weather:

Tire Adaptability: In cold weather, tire rubber hardens, reducing grip. To adapt to cold conditions, Hangzhou Kotter equips its flatbed semi-trailers with winter tires specifically designed for low temperatures. These tires utilize a rubber material that remains flexible in low temperatures, ensuring stability on icy and snowy roads.

Hydraulic System and Suspension Design: Cold weather can increase the viscosity of hydraulic oil, affecting the responsiveness and stability of the suspension system. Therefore, Hangzhou Kotter's hydraulic system utilizes winter-specific hydraulic oil, which maintains a low viscosity at low temperatures, ensuring proper operation in cold conditions. Furthermore, the vehicle's air suspension system automatically adjusts to temperature fluctuations to optimize vehicle stability.

Braking System: In cold weather, the brake system is susceptible to failure due to ice and snow. Hangzhou Kotter's flatbed semi-trailers are equipped with an efficient anti-freeze braking system to ensure optimal performance in severe cold weather. Furthermore, a wheel temperature monitoring system provides real-time feedback on temperature changes, ensuring timely brake system adjustments.

Performance in Rain and Snow

In rain and snow, the traction performance of flatbed semi-trailers is primarily affected by slippery roads and poor visibility. Slippery roads and accumulated snow can increase rolling resistance, reduce traction, increase braking distances, and even create safety hazards like skidding. Hangzhou Kotter's flatbed semi-trailers are designed with safety in adverse weather conditions in mind, implementing a series of measures to ensure performance in rainy and snowy conditions:

Anti-skid performance: On slippery roads, tire grip is crucial for safe traction. Hangzhou Kotter's flatbed semi-trailers are equipped with high-performance, anti-skid tires. These tires feature a specially designed tread pattern that quickly dissipates water and snow, reducing obstruction from water or snow, and enhancing friction between the tire and the road.

Braking system adaptability: Stopping distances can be significantly increased in rainy and snowy conditions. To enhance braking performance, Hangzhou Kotter's flatbed semi-trailers feature an Electronic Braking System (EBS). This system automatically adjusts braking force based on road conditions, preventing wheel lock and improving braking safety on slippery and wet roads.

Suspension system adjustment: To enhance stability in rainy and snowy conditions, Hangzhou Kotter's air suspension system automatically adjusts vehicle height based on load changes, ensuring stability and traction on complex roads.

Performance in Tropical Climates

Tropical climates are characterized by high humidity and temperatures, which significantly impact the performance of flatbed semi-trailers. High humidity can easily cause rust or corrosion on vehicle components, while high temperatures accelerate tire wear. To adapt to this environment, Hangzhou Kotter has implemented several technical measures:

Corrosion-resistant Design: In tropical climates, humid air can accelerate the corrosion of vehicle 7components. Hangzhou Kotter's flatbed semi-trailers feature an anti-corrosion coating, and the body and frame are constructed of corrosion-resistant materials, extending the vehicle's service life in humid environments.

Tires and Suspension System: High temperatures can lead to excessive tire wear. To ensure traction performance under prolonged, high-load operation, Hangzhou Kotter has selected high-temperature wear-resistant tires and incorporated high-temperature adaptability into the suspension system, ensuring excellent traction and stability even during extended, high-temperature operation.

English

English  中文简体

中文简体