-

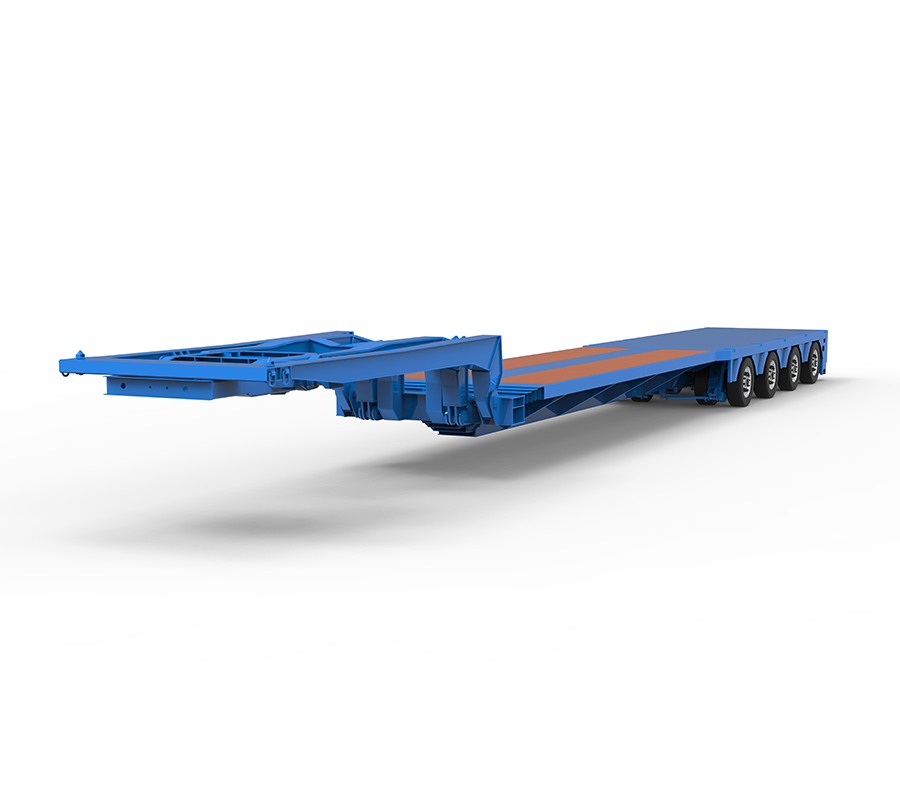

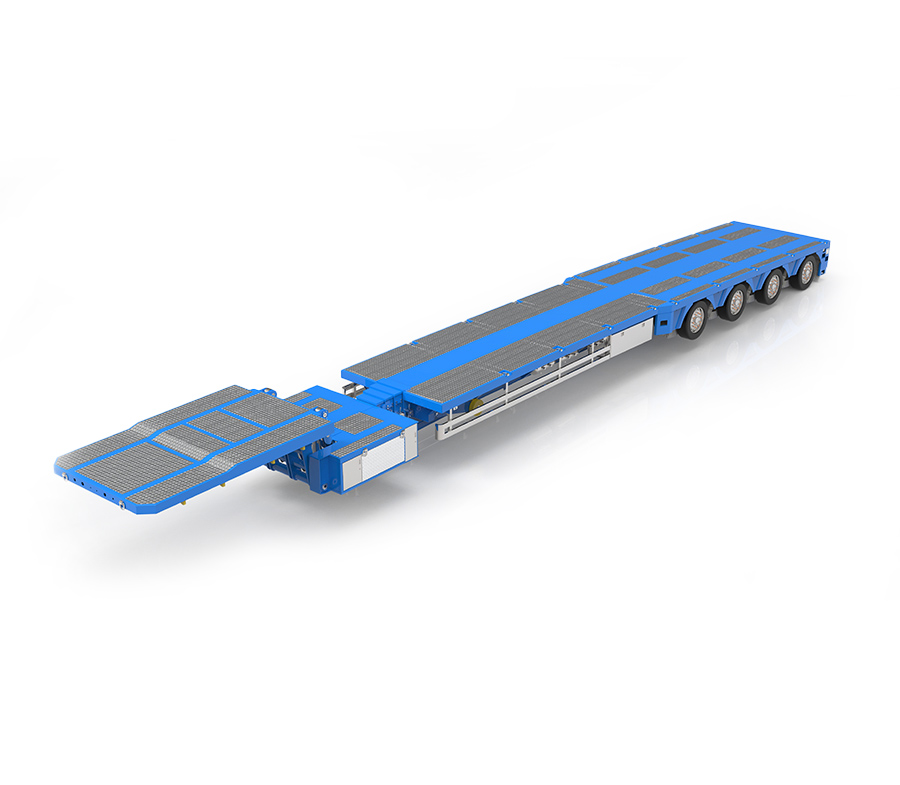

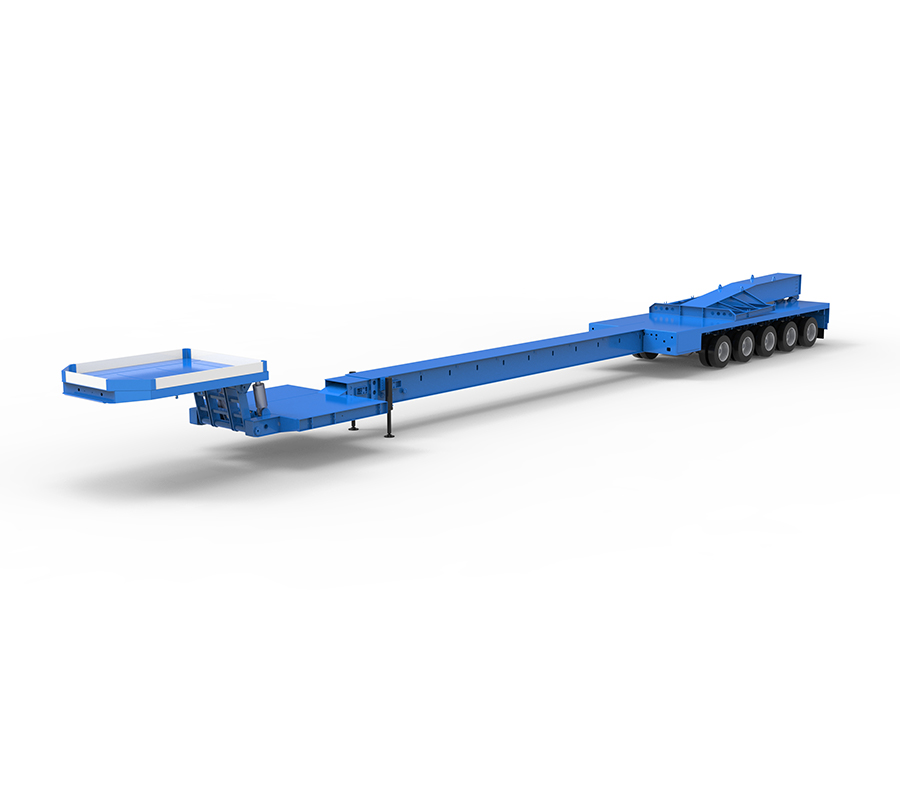

The Adjustable Gooseneck Low Flatbed Semi-Trailer has emerged as a game-changing solution for industries that rely on transporting oversized or heavy equipment. From construction machinery and industr...

READ MORE -

In the world of modern logistics and heavy cargo transportation, efficiency, stability, and adaptability are key. The KTG-4 hydraulic axles line trailer with 4 axle (SPT) stands out as a powerful solu...

READ MORE -

Precision Engineering and Stability: The Core of the Low Flatbed Precision Instrument Transport Semi-Trailer At the heart of the Low Flatbed Precision Instrument Transport Semi-Trailer lies a meticulo...

READ MORE -

What Is a Wind Turbine Tower Bridge and Why Is It Essential? The Wind Turbine Tower Bridge is a specialized structural device used during the assembly of wind turbine towers. Its main function is to c...

READ MORE

What types of wind turbine equipment are commonly transported by wind power transporters?

With the growing global demand for renewable energy, wind power has become one of the most important forms of energy. With the gradual advancement of wind power projects, especially the construction of large-scale wind farms around the world, the transportation of wind power equipment has become particularly important. Wind power transporters play a key role in this process. As heavy-duty vehicles specifically designed to transport wind power equipment, they must not only adapt to complex transportation environments but also ensure the safety and stability of the equipment during transport.

Types of Wind Power Equipment

Wind power equipment consists of several key components, each with different sizes, weights, and transportation requirements. Common wind power equipment includes:

Wind turbine mainframe: As the core component of a wind power plant, the wind turbine mainframe is typically the heaviest and largest component. Transporting a wind turbine mainframe requires a transporter with strong load-bearing capacity and good stability.

Wind turbine blades: Wind turbine blades are the largest and longest components of a wind power plant. Blades can often reach lengths exceeding 60 meters, requiring specialized transport vehicles with excellent flexibility and dispatch capabilities.

Wind Turbine Tower: The wind turbine tower is the structural component supporting the wind turbine and is typically transported in multiple sections. The tower's length and weight place high demands on transport vehicles, necessitating the use of specially designed multi-axle heavy-duty vehicles.

Wind Turbine Tower Base: The tower base, typically consisting of a concrete or steel foundation, is a crucial component of wind turbine equipment, requiring precise lifting and transport tools.

Application of Wind Turbine Transport Vehicles

The core function of wind turbine transport vehicles is to safely and promptly transport these massive wind turbine equipment components to the installation site. To accommodate these diverse equipment types, wind turbine transport vehicles feature a variety of technical configurations and design features. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has extensive experience in this area. Its products, such as high-tech heavy-duty hydraulic axle semi-trailers, SPMT modular vehicles, and wind turbine blade transport vehicles, can meet the diverse transportation needs of wind turbine equipment.

- Transporting Wind Turbine Blades

The length and shape of wind turbine blades dictate their unique transport characteristics. Transporting blades typically requires specially designed wind turbine blade transporters featuring height-adjustable axle systems, enabling safe transport without damaging the blades. The wind turbine blade transporters provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. are equipped with a multi-axle steering system and hydraulic suspension, enabling smooth transport of large wind blades over complex terrain and on narrow roads.

- Transporting Wind Turbine Generators

Due to their large size and weight, wind turbine generators require heavy-duty transport vehicles with strong carrying capacity. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s high-tech, heavy-duty hydraulic axle semi-trailers offer ample carrying capacity and stability, enabling efficient transport of wind turbine generators. These transporters are often equipped with variable wheelbase technology to ensure smooth transport on unstable terrain. Furthermore, these vehicles automatically adjust as needed to ensure the wind turbine generator does not tilt or shift during transport.

- Wind Turbine Tower Transportation

Wind turbine towers are typically transported in multiple sections, requiring specialized transport vehicles with long axles and adjustable trolleys. The heavy-duty semi-trailers and modular vehicles provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. offer excellent towing capacity and flexibility, adapting to the transportation needs of wind towers. SPMT modular vehicles are particularly effective for particularly long tower sections. With their flexible modular connections and adjustable load capacity, SPMT modular vehicles are suitable for a variety of complex terrains, enabling smooth transportation on narrow urban roads or rugged mountain roads.

- Wind Turbine Tower Base Transportation

Transporting wind turbine tower bases often involves very heavy items, necessitating the use of heavy-duty transport vehicles. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s hydro-pneumatic and hydraulic suspension systems provide stable load-bearing capacity, ensuring smooth and safe transportation. These specialized transport vehicles effectively reduce vibration and damage to the base during transportation, thereby ensuring the integrity of the wind turbine base.

Technical Advantages

The wind turbine transport vehicles provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. not only have a strong carrying capacity but also offer significant advantages in the following aspects:

Multi-axle steering system: This system allows the transport vehicle to more flexibly navigate narrow or complex road conditions, reducing the turning radius and ensuring smooth transportation.

Hydraulic suspension system: The hydraulic suspension system can adjust the vehicle height as needed, effectively absorbing vibrations during transportation and ensuring safe transportation of equipment.

Modular design: The SPMT modular vehicle can be combined into modules according to specific transportation needs, flexibly adapting to transport different types of wind turbine equipment.

Automatic adjustment function: With the continuous advancement of intelligent manufacturing technology, some wind turbine transport vehicles are equipped with automated control systems that monitor transportation status in real time and automatically adjust the vehicle body position to ensure safe transportation of equipment.

How do wind turbine transporters ensure equipment safety during transportation?

Multi-Axis Steering System: Flexible Maneuverability Ensures Safety

Windpower transporters, especially large ones used to transport wind turbine blades and towers, require exceptionally high levels of maneuverability and precise maneuverability. During transportation, especially on narrow roads, sharp turns, or in complex terrain, the vehicle's turning radius is a critical factor affecting equipment safety. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine transporters are equipped with a multi-axle steering system that automatically adjusts the steering angle of the wheels based on road conditions, significantly reducing vehicle roll and instability during transportation. This technology enables precise steering, preventing collisions and equipment damage caused by improper operation.

Hydraulic Suspension System: Smooth Transition and Vibration Prevention

Wind turbine equipment is particularly susceptible to uneven surfaces, vibrations, and impacts during transportation, which can cause damage or deformation. To address this issue, Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine transporters utilize a hydraulic suspension system. The hydraulic suspension system can adjust the height and levelness of the transport vehicle in real time, reducing vibration caused by uneven terrain or high speeds. This system ensures that the equipment remains stable during transport, preventing additional stress and damage.

The hydraulic suspension system is particularly important in transporting equipment such as wind turbine blades and towers. Due to their large size and long length, these equipment are susceptible to external factors such as wind and uneven road surfaces during transport, causing vibration and swaying. The hydraulic suspension system ensures a smooth transition during transport through precise adjustments, effectively reducing unnecessary damage.

Variable Wheelbase Design: Adapting to Diverse Transport Needs

The design of wind turbine transport vehicles must take into account the diverse range of equipment being transported. Different types of wind turbines, blades, towers, and other equipment vary significantly in size and weight, placing higher demands on the transport vehicle's flexibility and load-bearing capacity. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine transport vehicles feature a variable wheelbase design. This system adjusts the vehicle's wheelbase to meet actual transport needs, ensuring optimal stability under varying loads. This design allows the transport vehicle to adjust to the weight and volume of different equipment, ensuring the safest possible transport for both long wind turbine blades and heavier towers. The variable wheelbase optimizes the center of gravity of the transport vehicle, reducing the risk of tipping or tilting, further ensuring equipment safety during transport.

High-Precision Monitoring System: Real-Time Monitoring to Prevent Potential Risks

To further ensure equipment transportation safety, Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine transport vehicles are equipped with a high-precision monitoring system. This system uses sensors to monitor the vehicle's status in real time, including temperature, vibration, speed, and other indicators, while also monitoring the equipment's location and trajectory. The monitoring system provides real-time feedback on any abnormalities that may occur during transport, such as excessive vibration, speeding, or wheel misalignment, and automatically alerts the driver to take necessary safety measures.

This technology effectively prevents accidents caused by factors such as equipment overloading and vehicle operator errors. Especially when transporting large equipment such as wind turbine blades and towers, even the slightest anomaly can lead to damage. Therefore, the implementation of a real-time monitoring system enables transport vehicles to perform self-detection and timely adjustments during transport, ensuring the equipment remains intact.

Hydraulic Lifting Device: Precise Loading and Unloading

The loading and unloading of wind turbine equipment often requires precise positioning and efficient operation. To ensure safe and efficient loading and unloading, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has designed a hydraulic lifting device that precisely controls the lifting and lowering position of the equipment, ensuring that wind turbines, blades, and other equipment are supported as safely as possible during loading and unloading. The hydraulic lifting device precisely controls the lifting speed and height of the load through a hydraulic system, ensuring that the equipment is not damaged by loss of control.

In addition, the hydraulic system can adjust the equipment's position as needed to maintain the optimal center of gravity distribution during transport. This is crucial for transporting wind turbine equipment, especially wind blades and towers, as these equipment are often very heavy and susceptible to external impact. The hydraulic lifting device ensures safe loading and unloading of the equipment and reduces the risk of accidents.

Automated Intelligent Control System: Improving Safety and Efficiency

With the advancement of intelligent technology, the application of automated control systems in wind turbine transport vehicles is becoming increasingly widespread. The wind turbine transport vehicles provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. are equipped with an automated intelligent control system that automatically adjusts the vehicle's operating status based on real-time data, optimizing its route, speed, and load. This intelligent system effectively reduces human error during transportation and automatically avoids potential safety risks such as speeding and excessive vibration.

This system also interacts with the external environment in real time, helping the transport vehicles better adapt to complex geographical conditions and climate change, ensuring the safe transportation of wind turbine equipment.

What unique environmental challenges do wind turbine transporters face in the Middle East?

High temperatures and dust storms

The Middle East's extreme temperatures and frequent sandstorms are among the biggest challenges facing wind turbine transporters. High temperatures (especially in summer, often exceeding 40°C) can cause overheating of mechanical equipment, impacting the transporters' operational stability and transport efficiency. Furthermore, sandstorms increase wear and tear on the transporters, and in severe cases, can even cause vehicle breakdowns or transport delays.

Coping Strategies:

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine transporters are engineered to withstand extreme heat conditions by utilizing high-temperature-resistant materials and efficient heat dissipation systems. The hydraulic system, bearings, and other key components undergo special treatment to ensure efficient operation even in high-temperature environments. Furthermore, external components of the transporters, such as tires and bodywork, feature sand-resistant designs to effectively protect against dust and sand erosion. To address the challenges of sandstorms, multi-layer sealing designs and dust filters are extensively used throughout the wind turbine transporters to ensure equipment safety and reliability during transportation.

Narrow and Rough Road Conditions

Although most wind farms in the Middle East are constructed in open desert areas, road conditions remain complex and diverse. In some areas, particularly at more remote wind farm sites, transport vehicles may need to traverse narrow city streets, irregular desert roads, or uneven rural roads. The terrain and width of these roads restrict the maneuverability of vehicles transporting large wind turbines, increasing risks during transportation.

Strategy:

To address this challenge, the middle east windpower transporters provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. feature a multi-axle steering system and an adjustable wheelbase design. These systems enable the vehicle to maneuver more flexibly on narrow roads, reducing the risk of roll and loss of control during cornering. Specifically designed for the unique desert environment of the Middle East, the company's hydraulic suspension system automatically adjusts the vehicle's height to suit different terrain conditions, enhancing vehicle stability. Furthermore, the SPMT modular vehicle can be combined into modules according to the transport mission, flexibly adjusting the transporter's length and width to accommodate varying road conditions and wind turbine size.

Long-distance Transportation and High Transportation Costs

Wind power projects in the Middle East are often located in remote areas, and the transportation of wind turbine equipment often requires long, cross-country journeys. This long-distance transportation not only increases transportation costs but also creates the risk of wear and tear on vehicles and mechanical failure during long journeys. Furthermore, equipment instability can occur during extended transportation, especially over uneven roads, significantly increasing the risk of equipment damage.

Coping Strategies:

To address potential equipment safety issues during long-distance transportation, Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s middle east windpower transporters utilize a sophisticated monitoring system that monitors the equipment's status in real time during transportation, ensuring that all components remain operational during long-distance transport. Through real-time data transmission and remote diagnostics, the transport vehicles can promptly identify potential failures and take preventative measures. Furthermore, high-precision hydraulic systems and intelligent control systems ensure that the equipment is always in optimal transport condition, reducing the risk of mechanical failure associated with long-distance transportation.

The Large Size of Wind Turbine Equipment

The components of wind turbine equipment, including turbine blades, towers, and generators, are typically large and heavy. Especially in the Middle East, large wind farms often require transporting blades dozens of meters long and towers weighing hundreds of tons, placing extremely high demands on the design and load-bearing capacity of transport vehicles.

Strategy:

To address this challenge, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. designs and manufactures specialized vehicles suitable for transporting large wind turbines. For example, hydraulic axle semi-trailers and SPMT modular vehicles can be flexibly adjusted to the size and weight of the specific equipment, providing sufficient load capacity. Multi-axle steering systems and hydraulic suspension systems further ensure the stability and safety of the equipment during transportation, preventing equipment from tilting or damage due to vehicle instability.

Impact of Extreme Weather on Transportation

The Middle East not only faces high temperatures but also frequent extreme weather conditions such as strong winds and sandstorms. Wind turbine transport vehicles operating in these inclement conditions require strong durability and emergency response capabilities to cope with the threats posed by sudden weather changes to transportation safety. Countermeasures:

To address this issue, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. reinforced the exterior structure of its wind turbine transport vehicles, incorporating wind-resistant designs and waterproof and dustproof measures to effectively prevent damage to the vehicles and equipment from wind, sand, and rain. Furthermore, an intelligent autonomous driving system can adjust the transport vehicles' speed and direction in real time, helping them maintain stable operation in adverse weather conditions and minimizing transportation risks associated with weather-related factors.

What are the drive modes for wind turbine transport vehicles?

Single-axle drive

Single-axle drive is one of the most common drive modes and is typically used to transport lighter wind turbine components. For relatively small equipment, single-axle drive provides sufficient power for transport and is suitable for short-distance and light-load transport missions.

Advantages:

Simple structure, easy maintenance, and relatively low cost.

For small wind turbine equipment (such as small sections of wind turbine mainframes or lightweight components), single-axle drive transport vehicles offer sufficient load capacity.

Limitations:

When transporting heavier equipment, single-axle drive vehicles may not provide sufficient power and have poor stability.

For complex road conditions, such as bumpy terrain or long transport times, single-axle drive vehicles may struggle to ensure safe and efficient transport of equipment.

Company Product Applications:

In Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s product line, single-axle drive wind turbine transport vehicles are primarily used for small wind power projects or for the local transport of wind turbine components, such as small blade components or disassembled wind turbine units.

Dual-Axle Drive

Dual-axle drive is relatively common in wind turbine transport vehicles and is particularly suitable for transporting heavier equipment, such as wind turbine towers, generators, and other components. Dual-axle drive provides improved traction and is suitable for longer-distance transport.

Advantages:

Compared to single-axle drive, dual-axle drive provides greater power and traction capacity, ensuring stable transport, especially with heavier loads.

It is suitable for longer-distance transport and can handle challenging terrain.

Limitations:

Compared to single-axle drive, dual-axle drive leads to higher manufacturing and maintenance costs.

In extreme environments (such as deserts), additional power and support systems may be required to ensure stability.

Company Product Applications:

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s dual-axle drive transport vehicles are suitable for transporting most wind turbine towers and large wind blades, especially those requiring longer distances. Dual-axle drive provides greater stability and power, ensuring the safety of the equipment during transport.

Multi-axle Drive (including four-axle and six-axle drives)

Multi-axle drive is a core technology in heavy equipment transportation, particularly in the wind power industry. Multi-axle drive trucks are used to transport large, heavy wind turbine components, such as long wind blades and tower bases. Multi-axle drive systems offer greater load capacity and smoother transport.

Advantages:

Multi-axle drive offers a higher load capacity and is suitable for transporting extremely heavy and long wind turbine components, such as wind blades up to 70 meters long and heavy towers.

The multi-axle design distributes the load more evenly, reducing road pressure and improving transport stability and safety.

Equipped with a multi-axle steering system, the truck can maneuver more flexibly in complex road conditions, especially on narrow urban roads or in complex natural terrain, effectively reducing space requirements for U-turns and turns.

Limitations:

Compared to single-axle and two-axle drive systems, they are more expensive and are suitable for long-distance, large-scale transport.

In extreme road conditions, such as slippery or very uneven roads, enhanced tire and suspension protection is required. Product Applications:

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s multi-axle drive transporters offer exceptionally high load capacity and stability, particularly for transporting wind turbine blades and towers. These transporters effectively handle complex transport tasks, ensuring the equipment remains intact during transportation. Especially for long wind blades and heavy towers, multi-axle drive transporters offer a perfect solution for handling long wind blades and heavy towers in a variety of challenging environments.

Hydraulic Drive

Hydraulic drive is often used in conjunction with a hydraulic suspension system and is widely used in applications requiring precise adjustment of the transport vehicle's height and load. Hydraulic drive provides greater stability and control accuracy during the transport of wind turbine equipment, particularly for transporting wind blades, where the hydraulic system better accommodates the delicate demands of the equipment.

Advantages:

Through precise control of the hydraulic system, hydraulic drive enables height adjustment during transport, preventing damage to the equipment caused by uneven roads or vibrations during transport.

Hydraulic drive offers greater power and efficiency than traditional mechanical systems, offering irreplaceable advantages, particularly in specialized environments requiring multi-axle steering and adjustment.

The hydraulic system can adjust the vehicle's center of gravity, ensuring the vehicle's stability. Limitations:

Hydraulic systems have relatively high maintenance costs and require high system precision.

Hydraulic drives may still require additional power in some complex terrains, especially in extremely hot or humid environments.

Company Product Applications:

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s hydraulically driven transport vehicles offer significant advantages in the precise transportation of wind turbine blades and towers. The use of hydraulic systems not only increases the transport vehicle's load capacity but also ensures safe and smooth equipment transportation through precise control.

SPMT Modular Vehicle (Self-Propelled Modular Transporter)

The Self-Propelled Modular Transporter (SPMT) is a highly flexible transport method, typically used to transport oversized or extremely heavy equipment. The SPMT vehicle consists of multiple independent modules, each capable of independent drive and steering. Modules can be added or removed as needed to flexibly meet various transport requirements.

Advantages:

Provides extreme flexibility and customizability, allowing the length, width, and weight of the transport vehicle to be adjusted to meet the specific requirements of the transport mission. Suitable for transporting ultra-large wind turbine equipment, such as wind blades and towers, it can precisely transport equipment across complex terrain.

The multi-module design provides a smoother transport process, reducing equipment damage caused by uneven roads.

Limitations:

Highly expensive, suitable for large-scale projects or specialized transport tasks.

Requires high technical support and training, and is relatively complex to operate.

Company Product Applications:

The SPMT modular transport vehicle provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. is widely used to transport equipment in ultra-large wind turbine projects. The SPMT's flexibility and high load capacity ensure safe equipment transportation, especially in complex terrain or extreme weather conditions.

English

English  中文简体

中文简体