-

The Adjustable Gooseneck Low Flatbed Semi-Trailer has emerged as a game-changing solution for industries that rely on transporting oversized or heavy equipment. From construction machinery and industr...

READ MORE -

In the world of modern logistics and heavy cargo transportation, efficiency, stability, and adaptability are key. The KTG-4 hydraulic axles line trailer with 4 axle (SPT) stands out as a powerful solu...

READ MORE -

Precision Engineering and Stability: The Core of the Low Flatbed Precision Instrument Transport Semi-Trailer At the heart of the Low Flatbed Precision Instrument Transport Semi-Trailer lies a meticulo...

READ MORE -

What Is a Wind Turbine Tower Bridge and Why Is It Essential? The Wind Turbine Tower Bridge is a specialized structural device used during the assembly of wind turbine towers. Its main function is to c...

READ MORE

What are the main types of special application trailers?

A special application trailer is a non-standard trailer designed for transporting specific cargo or specific operations. Its structure, load capacity, suspension system, and powertrain are customized based on the transported object and environment.

High-Strength Hydraulic Multi-Axle Semi-Trailer

High-strength hydraulic multi-axle semi-trailers are key equipment for carrying heavy and extra-long cargo and are widely used in transporting large machinery, steel structures, and energy equipment. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s hydraulic multi-axle semi-trailers utilize high-strength steel and an advanced hydraulic suspension system, enabling independent adjustment of multiple axles to increase load capacity and reduce road pressure. When transporting irregular or extra-long cargo, the hydraulic system adjusts trailer height and axle load distribution to ensure safety and stability. These trailers often incorporate retractable or foldable designs, significantly enhancing transport flexibility and making them suitable for specialized applications such as bridges and wind turbine tower sections.

Modular SPMT Vehicles

The modular self-propelled modular transporter (SPMT) is a high-tech device designed for heavy-duty transport. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s SPMT product features a modular design that allows for flexible axle combinations based on cargo size and weight, achieving micron-level precision positioning and uniform load distribution. This type of trailer is primarily used in shipbuilding, nuclear power equipment transport, and large industrial equipment handling. Its modular design not only improves transport efficiency but also reduces road and bridge load risks, providing a professional solution for heavy-duty logistics.

Precision Instrument Transport Semi-trailer

Precision instrument transport semi-trailers are designed for high-value, fragile cargo, such as scientific research equipment, medical devices, and electronic equipment. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. installs high-precision hydro-pneumatic suspension or hydraulic shock-absorbing systems on the trailer chassis to minimize vibration during transport, thereby preventing damage to the equipment. The suspension system and vehicle structure are meticulously calculated to ensure even weight distribution. The cargo platform size and mounting method can also be customized to meet diverse transport requirements. This type of trailer is widely used in scientific research, medical treatment, and high-precision industrial transport.

Wind Turbine Blade Transport Semi-Trailers

Wind turbine blades are typically long and lightweight, requiring extremely high bending and torsional load capacity during transport. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s wind turbine blade transport semi-trailers utilize adjustable support frames and a hydraulic lift system to precisely support and secure the blades according to their length and curvature. Furthermore, the trailer's axle layout and steering system are expertly designed to adapt to narrow roads and long-distance transport, ensuring efficient and safe transport of wind turbine equipment.

Construction Machinery Transport Semi-Trailers

Construction machinery transport semi-trailers are used for long-distance transport of large construction machinery such as excavators, bulldozers, and cranes. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. offers a variety of variable wheelbase, hydraulic lift, and powered gooseneck designs, ensuring easy loading of heavy machinery while reducing structural stress and road pressure during transport. The trailer's cargo platform length, width, and load capacity can be customized based on the size and weight of the machinery, making transport of large construction equipment safer and more efficient.

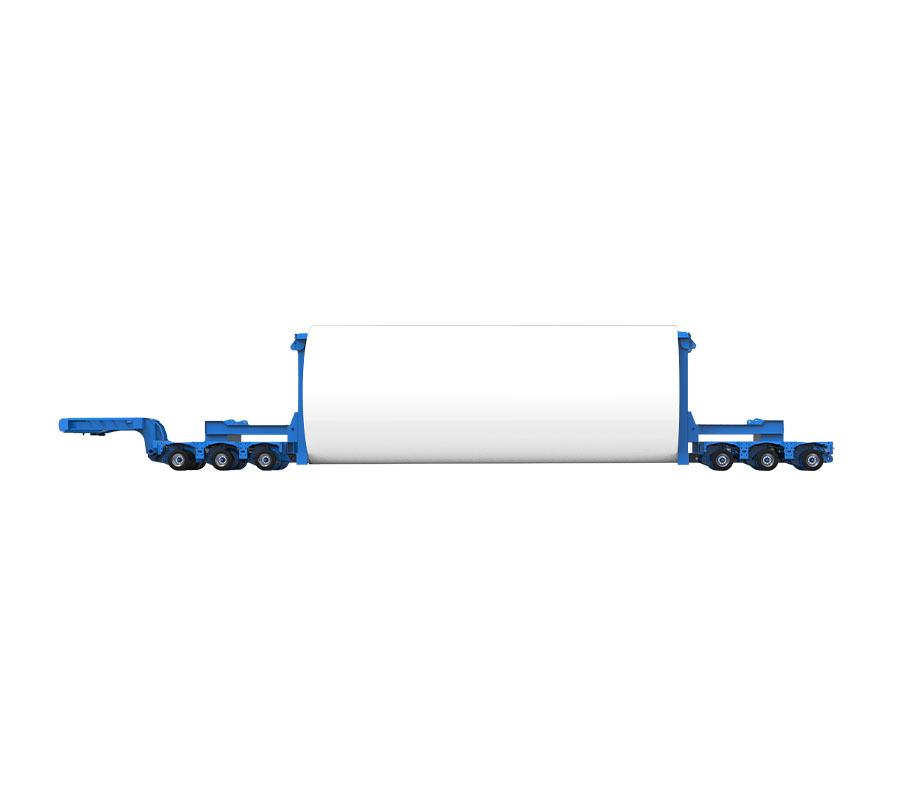

Tower Clamping Transport Semi-trailer

Tower clamping transport semi-trailers are primarily used for transporting steel structure towers or wind turbine towers, ensuring that cargo does not shift during transport. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s tower transport trailers feature an adjustable clamping mechanism and a high-strength chassis, enabling multi-angle fixation and balanced load distribution to accommodate towers of varying diameters and lengths. The clamping mechanism works in concert with the suspension system to maintain high stability during long-distance transport.

Aluminum Curtainside Semi-trailer

Aluminum curtainside semi-trailers combine lightweight design with practicality, making them suitable for both short- and long-distance transport of logistics, industrial components, and bulk cargo. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes lightweight aluminum alloy materials and a curtainside structure to improve loading and unloading efficiency and reduce vehicle weight, providing customers with an economical, durable, and easy-to-maintain transport solution.

How to design a special application trailer's suspension system based on the type of cargo being transported

Suspension Design for Precision Instruments and High-Value Cargo

Semi-trailers transporting precision instruments, such as scientific research equipment, medical devices, and precision electronic equipment, are extremely sensitive to vibration and shock. To reduce micro-vibrations and impact during transportation, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes high-precision hydro-pneumatic or hydraulic suspension in its design. This system adjusts suspension stiffness based on the load weight and cargo center of gravity, achieving multi-level cushioning. The suspension system's adjustment range and sensitivity are precisely calculated, ensuring vehicle stability at high speeds, during deceleration, and during cornering, significantly reducing the risk of cargo damage. Furthermore, through a multi-axle layout and optimized load distribution, the suspension system balances wheel loads, avoids excessive localized stress, and ensures stability during long-distance transport.

Suspension Design for Heavy Machinery and Construction Equipment

Construction machinery transport trailers often carry extremely heavy and complex cargo, such as excavators, cranes, and bulldozers. For this type of trailer, a hydraulic multi-axle suspension system is the preferred choice. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. utilizes hydraulic cylinders and adjustable support arms to enable each axle to independently adjust its height and load capacity, adapting to uneven road surfaces, distributing the pressure of heavy loads, and protecting the chassis structure from stress concentration. The variable wheelbase design, combined with the suspension system, ensures more balanced load distribution when the trailer turns or negotiates ramps, enhancing transport safety. Furthermore, the hydraulic suspension, combined with a powered gooseneck, adjusts the load between the front and rear wheels, making loading and unloading heavy machinery smoother and reducing operational risks.

Suspension Design for Wind Turbine Blades and Long Cargo

Transporting wind turbine blades and other long cargo requires extremely high lateral stability and longitudinal bending resistance for trailers. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. typically utilizes a multi-link hydraulic suspension system for these trailers. Each axle independently responds to road surface changes, while lateral stabilizers reduce roll. The height-adjustable suspension system maintains a low center of gravity and balanced load distribution during different transport stages, preventing blades from bending or twisting during transport. In addition, the retractable body is linked to the suspension system, enabling flexible adjustment of the load support point, ensuring the safety of long cargo throughout the transport process.

Suspension Design of Modular Transport Vehicles (SPMTs)

SPMTs are used to transport heavy or oversized equipment, requiring a suspension design that balances flexibility and load-bearing capacity. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s SPMTs utilize an independent hydraulic suspension system, allowing each axle to adjust individually based on the module configuration and cargo weight, ensuring even load distribution. The suspension system also incorporates multi-axle steering technology, enabling high maneuverability on narrow roads and in complex construction sites. Furthermore, the suspension system automatically adjusts the vehicle's height to accommodate bridges or construction platform height requirements, ensuring safe passage of transported equipment.

Suspension Design for Lightweight and General Industrial Cargo

For aluminum curtain-side semi-trailers or general industrial cargo transport, the suspension system prioritizes shock absorption, comfort, and durability. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. typically uses airbag suspension or combined hydro-pneumatic suspension to reduce the vehicle's weight burden on the suspension system while improving transport stability. This design balances economy and reliability, meeting the diverse needs of long-distance logistics and urban transportation.

What are the special requirements for the braking system of special application trailers?

Braking Requirements Under High Load Capacity

The transport of heavy machinery, wind turbine towers, and large structural components places extremely high load capacity demands on trailer braking systems. When designing the braking systems for high-strength hydraulic axle semi-trailers and multi-axle hydraulic suspension semi-trailers, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. prioritized the matching of axle loads with the gross vehicle weight. The multi-axle balanced braking design ensures even braking force distribution across all axles under heavy loads, preventing single axle overload or tire lock, thereby ensuring vehicle stability during descents, corners, and emergency braking.

Braking Smoothness for Transporting Precision Instruments and Fragile Cargo

For semi-trailers transporting precision instruments and high-value, fragile cargo, braking system smoothness is crucial. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. optimizes the combined pneumatic and hydraulic braking system to ensure smooth braking force distribution based on the load and cargo center of gravity. This prevents vibration and shock caused by sudden stops or sudden braking force changes, protecting the integrity of the cargo. Furthermore, the braking response can be linked with the vehicle's hydraulic suspension system to further reduce impact on cargo during braking, ensuring the safety of precision equipment during long-distance transport.

Braking Coordination for Extra-Long Cargo and Modular Transport Vehicles

Extra-long cargo transport semi-trailers and SPMT modular vehicles are significantly longer and have many more axles than ordinary trailers, requiring their braking systems to possess multi-stage coordinated control capabilities. Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s design utilizes a multi-stage pneumatic-hydraulic brake system. Each module or axle group independently responds to braking signals, ensuring optimal braking force for each axle during curves, intersections, and slopes, thereby preventing vehicle sway, tailing, or deviation. Modular vehicles can adjust braking strategies based on cargo weight and length, achieving dynamic load control and multi-axle coordinated braking to ensure safe and reliable transport of oversized cargo.

Safe Braking Requirements for Downhill and Complex Road Conditions

Special-purpose trailers require stable downhill control when transporting in mountainous areas, on construction sites, or on bridges. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. incorporates high-precision proportional valves and multi-stage braking force adjustment technology into its braking system, enabling trailers to maintain constant deceleration on long downhill sections, preventing tire lock and vehicle skidding. Hydraulic auxiliary braking can be linked with the hydro-pneumatic suspension system to adjust axle load distribution in real time, enhancing braking friction and improving vehicle safety on downhill descents.

Redundancy and Emergency Braking Design

To meet the stringent safety requirements of specialized transport missions, Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s special-purpose trailer braking systems typically feature a dual-redundancy architecture, including a primary braking system and an auxiliary braking system. Even in the event of a primary system failure, the auxiliary braking system can still effectively decelerate and stop the vehicle, ensuring the safety of both cargo and vehicle. Furthermore, the emergency braking control logic works in conjunction with the multi-axle steering and hydraulic suspension systems to ensure vehicle stability and steering controllability in emergency situations, improving transport reliability.

High Environmental Adaptability Requirements

Special-purpose trailers often operate in extreme environments, including high and low temperatures, slippery roads, and muddy construction sites. Hangzhou Kotter Intelligent Manufacturing Co., Ltd. selected high-temperature and corrosion-resistant materials for its braking system design. It also features an intelligent control system that dynamically adjusts braking force based on load, road friction coefficient, and vehicle speed. This ensures efficient braking performance in all conditions, meeting diverse transport requirements.

Collaborative Design with Suspension and Steering

The collaborative design of the braking system with the suspension and multi-axle steering systems is a major technical advantage of Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s special-purpose trailers. By linking brake signals with the hydraulic suspension and steering systems, the trailer automatically adjusts axle force during cornering or load changes, optimizing braking force distribution, reducing tire wear, and improving vehicle maneuverability and transport safety.

English

English  中文简体

中文简体